TungShortCut – Shaft Parts – AH725

REDUCTION OF MATERIAL COSTS

Previously, parting-off was performed using a 1.2 mm width insert.

After switching to a 1.0 mm width TungShortCut insert, stable machining was achieved without issues such as chip evacuation problems or insert breakage.

By changing to a 1.0 mm width insert, a reduction in material costs became possible.

Share

| Industry | Automotive |

|---|---|

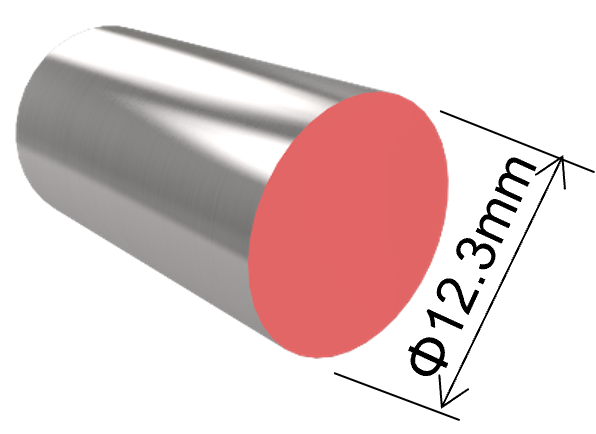

| Component | Shaft |

| Material ISO code |

|

| Work material | SUS430 |

| Machine(spindle type) | Swiss Lathe |

| Tool family | Grooving |

| Tool category | Parting off |

| Product name | TungShortCut |

| TSR No. | 5182T |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | QC12-JTTELS1D16-CHP | 12X12 shank |

| Insert | DGS100S-003 | 2 corner insert |

| Edges par insert | 2 | 2 |

| Cutting width | 1.0 | 1.2 |

| Grade | AH725 | PVD |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 3000 | 3000 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 100 | 100 |

| Feed f (mm/rev) | 0.04 | 0.04 |

| Coolant | Wet(External) | Wet(External) |