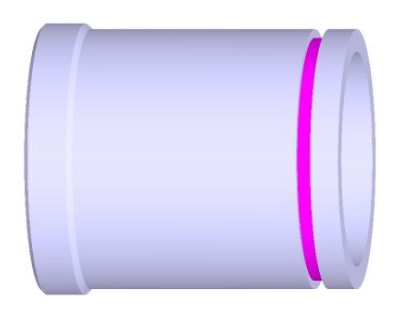

TetraForceCut – Brake cover – FC250

IMPROVED PRODUCTIVITY AND TOOL LIFE

A three-corner insert was previously used for machining brake covers on construction machinery. We proposed the TetraForce-Cut instead.

The workpiece material is FC250, and to improve tool life, the wear-resistant AH8005 grade was applied.

The latest AH8005 grade enhanced tool life by 1.5 times, and switching from the conventional three-corner insert to the four-corner TetraForce-Cut significantly improved tool life per insert.

Additionally, cutting speed was increased, contributing to higher machining efficiency.

Share

| Industry | Heavy |

|---|---|

| Component | Brake cover |

| Material ISO code |

|

| Work material | FC250 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Grooving |

| Tool category | External grooving |

| Product name | TetraForce-Cut |

| TSR No. | 5107T |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | STCR2525-27 | 25x25 Shank |

| Insert | TCM27-250-030 | 3 corner insert |

| Edges par insert | 4 | 3 |

| Cutting width | 2.5 | 2.5 |

| Grade | AH8005 | Un coated carbide |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 120 | 80 |

| Feed f (mm/rev) | 0.08 | 0.08 |

| Depth (mm) | 3.5 | 3.5 |

| Coolant | Wet(External) | Wet(External) |