TungMeister – Motor Shaft – AH725

IMPROVED PRODUCTIVITY

The high-speed steel (HSS) center drill currently used for center drilling of motor shafts, a type of automotive part, has been resulting in slow machining times.

For a newly launched motor shaft, TungMeister was proposed and tested.

By increasing the cutting speed and feed rate, a 4.7 times improvement in machining efficiency was achieved, successfully addressing the challenge of reducing machining time.

Share

| Industry | Automotive |

|---|---|

| Component | Motor Shaft |

| Material ISO code |

|

| Work material | SCr420 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Milling |

| Tool category | Drilling |

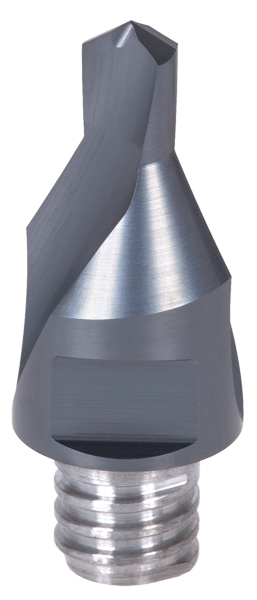

| Product name | TungMeister |

| TSR No. | 5103M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | VSSD12L090S08-S | |

| Effective number of teeth | 2 | 2 |

| Cutting diameter | 5.13 | 6 |

| Insert | VDP513L07.2A30-02S08 | Solid center drill |

| Number of cutting edges | 1 | 1 |

| Grade | AH725 | Uncoated HSS |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 40 | 15 |

| Feed f (mm/rev) | 0.15 | 0.1 |

| Feed speed Vf (mm/min) | 372 | 80 |

| Hole depth (mm) | 7.2 | 7.2 |

| Coolant | Wet(External) | Wet(External) |