AddMultiTurn – Bearing – T9215

IMPROVED TOOL LIFE AND COST

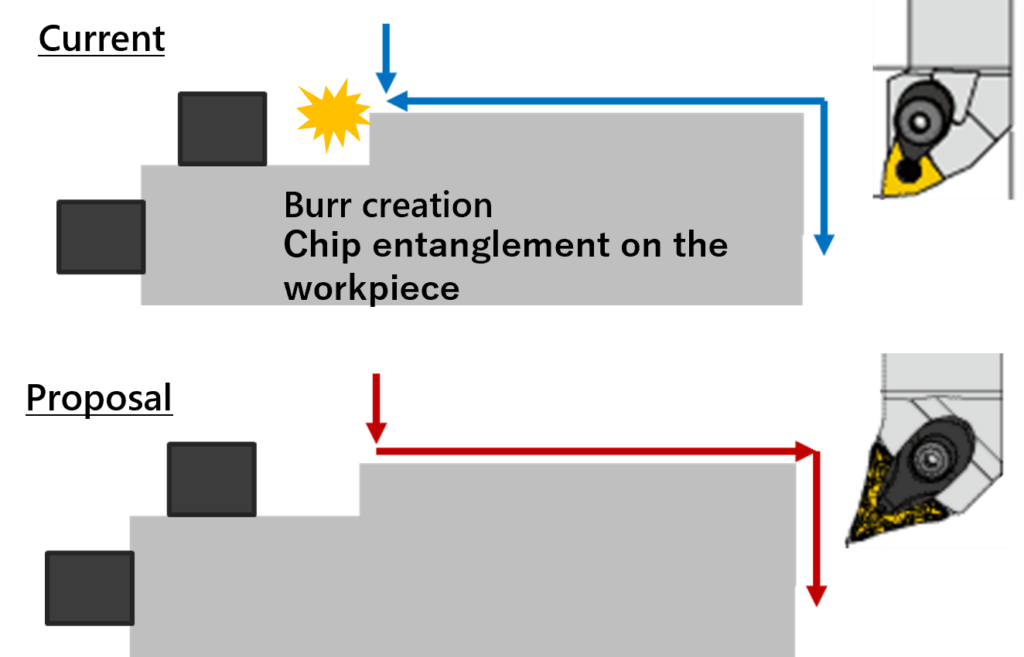

ISO inserts were being used, but issues such as burrs and ring-shaped chips wrapping around the workpiece occurred. Additionally, there was a request to improve the short tool life.

By applying the AddMultiTurn, Tungaloy changed the external turning process from front turning to back turning with a single pass. This change suppressed burr formation and resolved the problem of chip entanglement. As a result, AddMultiTurn achieved a 1.15x increase in machining efficiency, consolidation of ISO inserts from two types to one, and a 1.4x extension in tool life.

Share

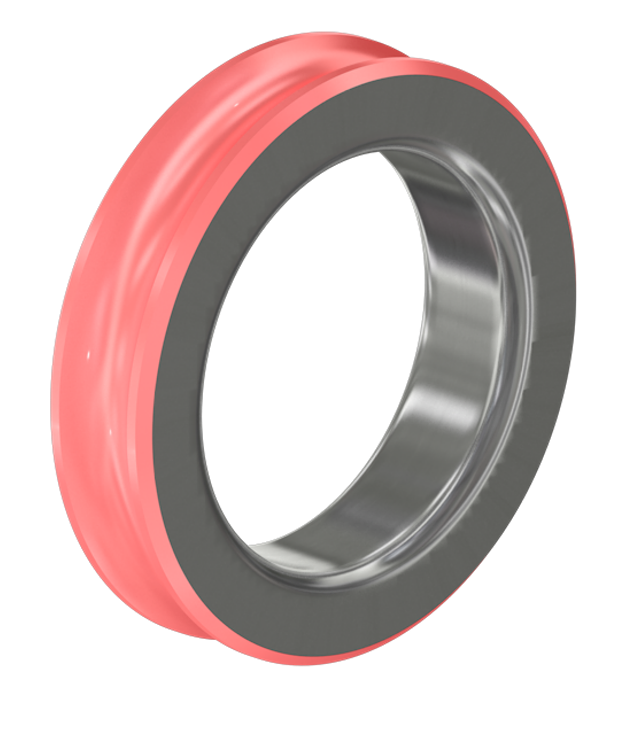

| Industry | Bearings |

|---|---|

| Component | Bearing |

| Material ISO code |

|

| Work material | STKM13A |

| Machine(spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | External & Face turning |

| Product name | AddMultiTurn |

| TSR No. | 5047T |

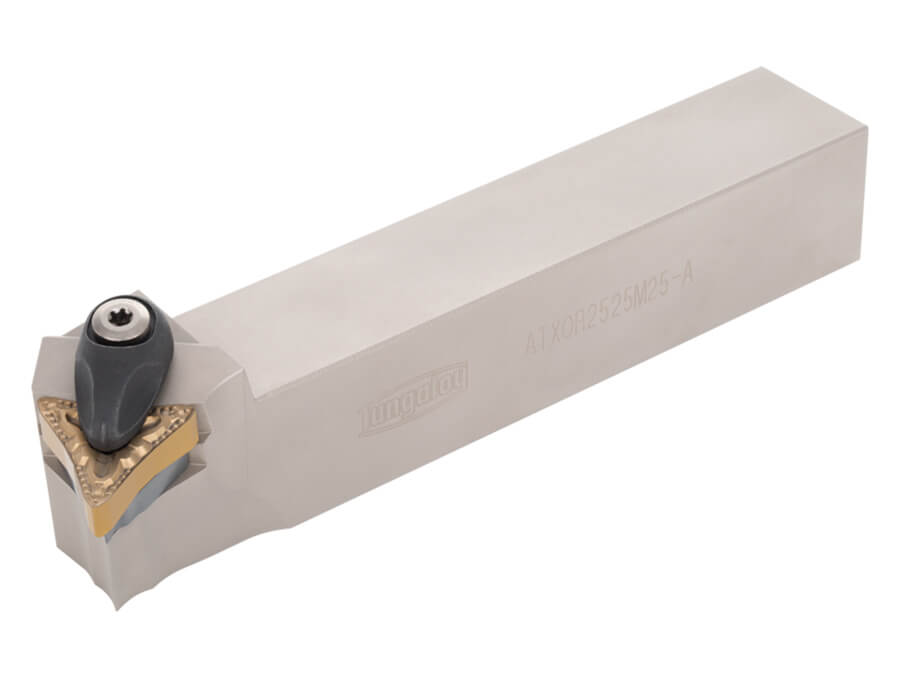

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Insert | 6V-TOMG250604F-TSF | WNMG080408-Middle chip breaker |

| Edges par insert | 6 | 6 |

| Grade | T9115 | CVD P15 |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 200 | 140 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 150 | 130 |

| Feed f (mm/rev) | 0.1 | 0.1 |

| Depth of cut ap (mm) | 0.15 | 0.15 |

| Coolant | MQL | MQL |