TungMeister – Mold – AH725

IMPROVED PRODUCTIVITY & TOOL LIFE

Quick tool change

- Compared to Competitors solid endmill, TungMeister enables tool change on machine by replacing only the head, shortening the machine downtime and thus improving productivity under the same cutting conditions.

Longer tool life

-Due to the excellent wear and fracture resistance of AH725 grade, TungMeister provides 1.4 times longer tool life than the competitor.

Share

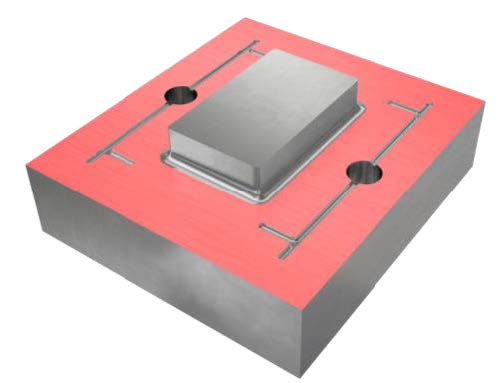

| Industry | Die & Mold |

|---|---|

| Component | Mold |

| Material ISO code |

|

| Work material | Steel alloy |

| Machine(spindle type) | CNC Lathe |

| Tool family | Milling |

| Tool category | Profiling |

| Product name | TungMeister |

| TSR No. | 256M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | VSSD12L110S08-C | Φ12-z=4 Solid endmill |

| Cutting diameter | 12 | 12 |

| Insert | VED120L09.0R05-04S08 | |

| Number of cutting edges | 4 | 4 |

| Grade | AH725 | Carbide |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 170 | 170 |

| Feed per tooth f/z (mm/t) | 0.07 | 0.07 |

| Feed speed Vf (mm/min) | 1263 | 1263 |

| Depth of cut ap (mm) | 0.25 | 0.25 |

| Width of cut ae (mm) | 0.1 | 0.1 |

| Coolant | Air | Air |