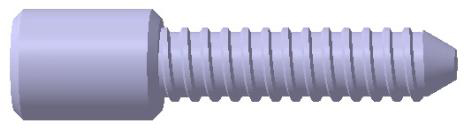

TetraForce-Cut- Implant – AH725

IMPROVED TOOL LIFE

Good chip evacuation

- The conventional insert often fractured when machining up to 2000 pcs/C due to high cutting resistance resulted from the chipbreaker. With a sharp cutting edge and dimpled chipbreaker, TetraForce-Cut provides excellent chip evacuation and stable machining in the machining of stainless steel!

High wear resistance

- The combination with AH725, which has a good balance between wear resistance and fracture resistance, achieves 1.5 times longer tool life (3000 pcs/C).

Share

| Industry | Medical |

|---|---|

| Component | Implant |

| Material ISO code |

|

| Work material | X6CrNiMoTi17-12-2 |

| Machine(spindle type) | Multi-axis Lathe |

| Tool family | Grooving |

| Tool category | Parting off |

| Product name | TetraForce-Cut |

| TSR No. | 251T |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | STCL1212-27 | 12X12 shank |

| Insert | TCS27-200-020 | 2mm width insert |

| Cutting width | 2.0 mm | 2.0 mm |

| Grade | AH725 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 70 | 70 |

| Feed f (mm/rev) | 0.05 | 0.05 |

| Coolant | Water soluble | Water soluble |