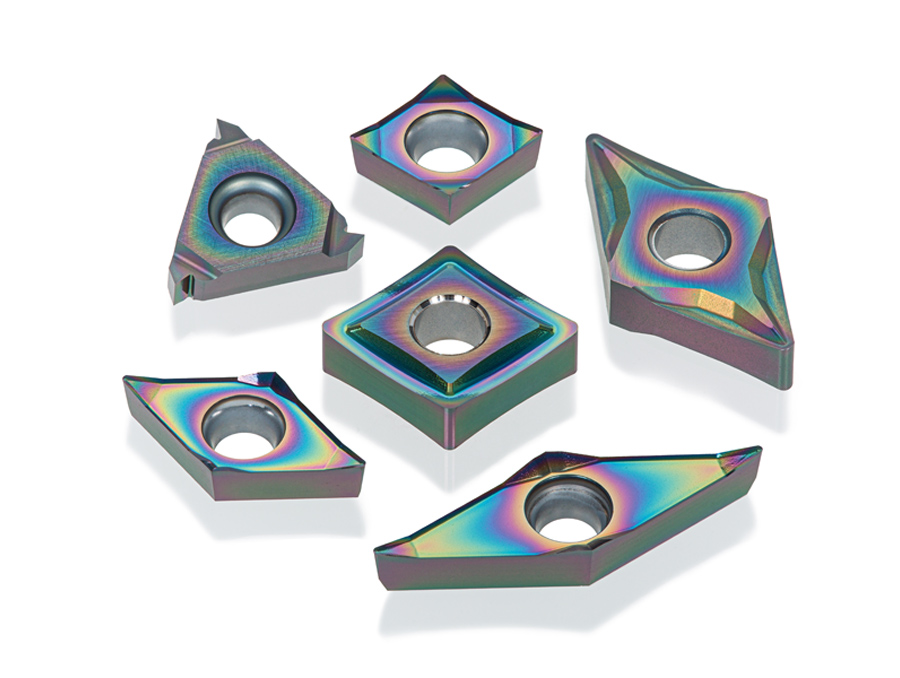

Excellent built-up edge resistance and high surface quality

Tungaloy original DLC coating grade, DS2000 for non-ferrous alloys

- Excellent built-up edge resistance achieves high quality glossy machined surface.

- The coating with high hardness and excellent heat resistance reduce wear.

- Outstanding coating adhesion technology provides stable and reliable machining.

DS2005 was tested with the aim of improving the quality of the machined surface. As a result, it was possible to machine for the same service life as the current product. It also achieved a better machined surface condition than the current product. While chipping occurred with the current product, which is thought to be the cause of the deterioration of the machined surface, DS2005 showed no chipping and exhibited normal wear.