DS2000-Spacer parts-DS2005

Excellent built-up edge resistance and high surface quality

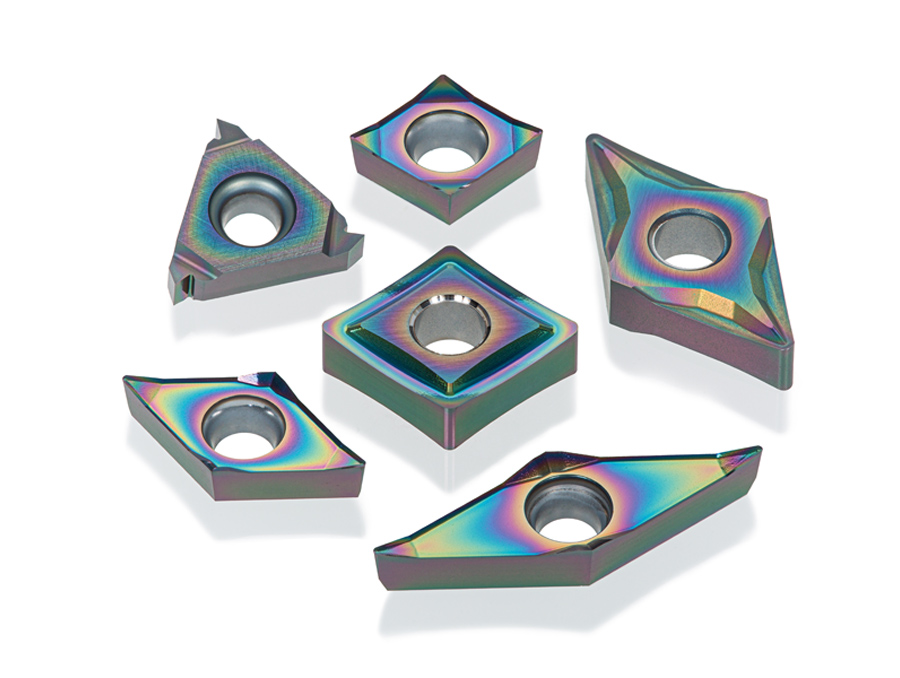

Tungaloy original DLC coating grade, DS2005 for non-ferrous alloys

- Excellent built-up edge resistance achieves high quality glossy machined surface.

- The coating with high hardness and excellent heat resistance reduce wear.

- Outstanding coating adhesion technology provides stable and reliable machining.

Previously, carbide grades were used, but DS2000 was tested to improve the machined surface condition and extend tool life.

As a result, DS2005 produced an excellent machined surface from the initial machining stage, and achieved stable machining up to a machining constant of 1,000.

Share

| Industry | Engineering |

|---|---|

| Component | Spacer |

| Material ISO code |

|

| Work material | A5052 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | External turning |

| Product name | DS2000 |

| TSR No. | 5494T |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | Standard tool holder | Standard tool holder |

| Insert | DCGT11T302-AL | DCGT11T302-** |

| Edges par insert | 2 | 2 |

| Grade | DS2005 | Cemented carbide grade |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 1000 | 1000(unstable) |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 160 | 160 |

| Feed f (mm/rev) | 0.1 | 0.1 |

| Depth of cut ap (mm) | 0.5 | 0.5 |

| Coolant | Wet | Wet |