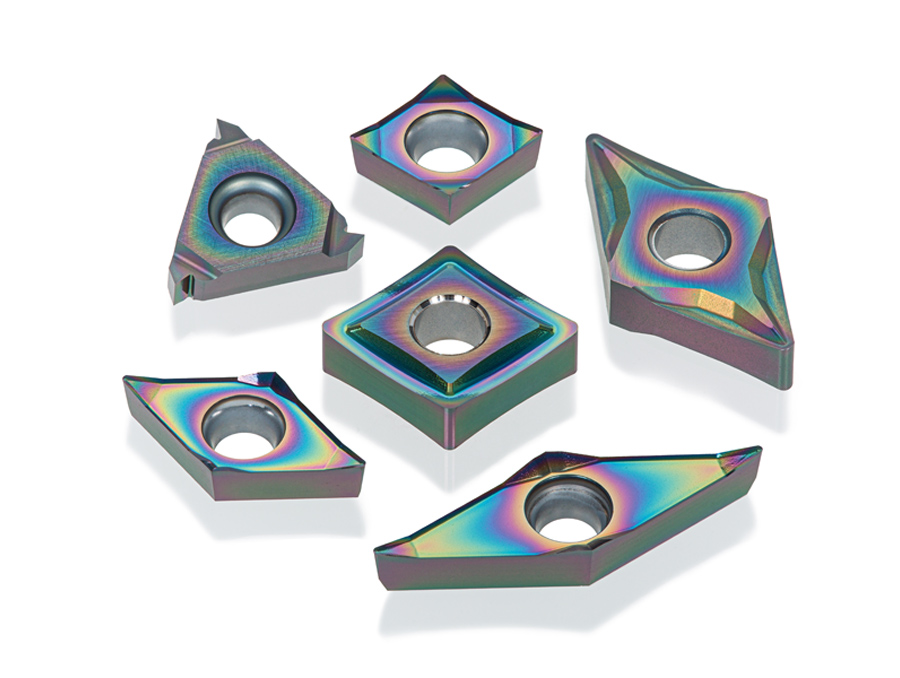

Excellent built-up edge resistance and high surface quality

Tungaloy original DLC coating grade, DS2005 for non-ferrous alloys

- Excellent built-up edge resistance achieves high quality glossy machined surface.

- The coating with high hardness and excellent heat resistance reduce wear.

- Outstanding coating adhesion technology provides stable and reliable machining.

Because the machining was for internal diameters and the parts were cast, there was a large variation in cutting depth, and with current carbide materials, the variation in lifespan due to the occurrence of sudden chipping was a major problem, so DS2005 was tested. As a result, up to the machining constant of 700, there was no abnormal damage such as chipping, and normal wear was observed, making stable machining possible.