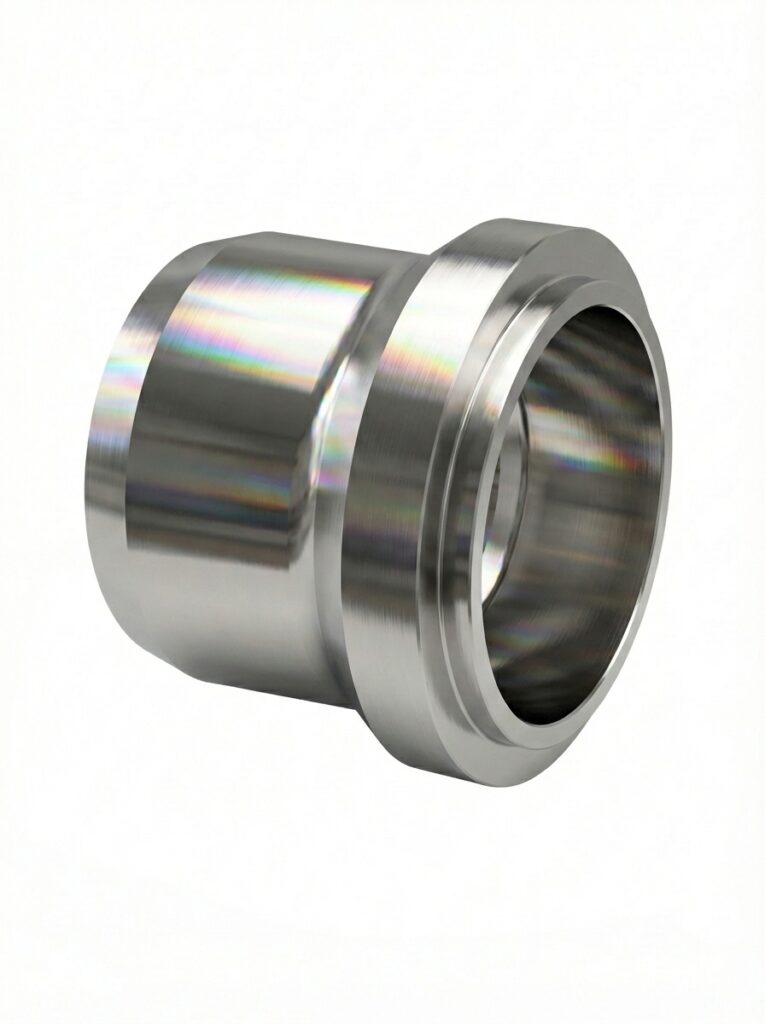

Excellent built-up edge resistance and high surface quality

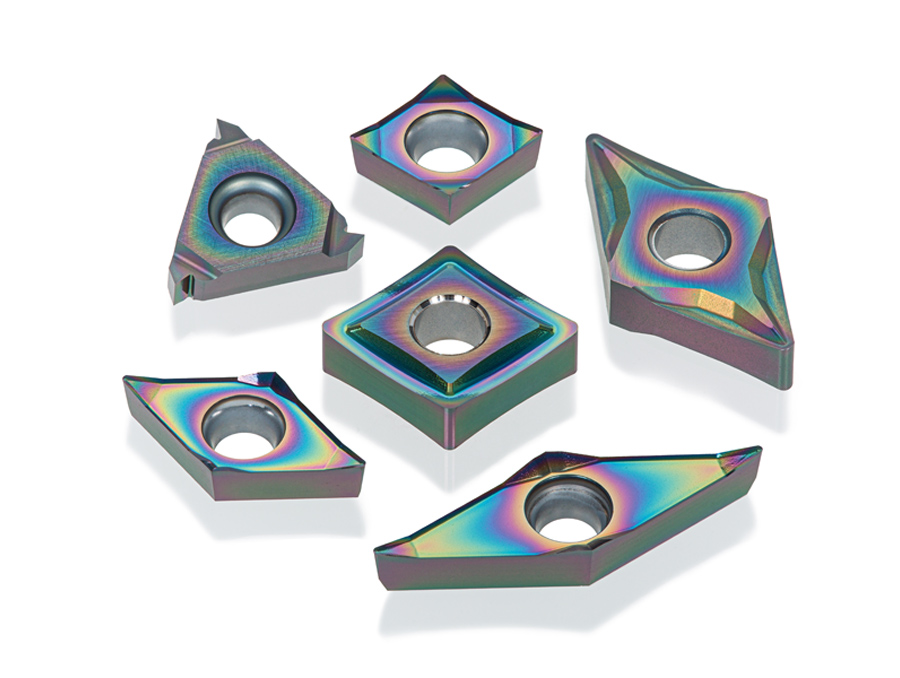

Tungaloy original DLC coating grade, DS2005 for non-ferrous alloys

- Excellent built-up edge resistance achieves high quality glossy machined surface.

- The coating with high hardness and excellent heat resistance reduce wear.

- Outstanding coating adhesion technology provides stable and reliable machining.

DS2005 was tested against other companies' DLC materials. As a result, it achieved a tool life 1.25 times longer. Regarding the machined surface condition, which is the criterion for determining tool life, the competitor's product turned cloudy and whitish around 120 units of machining, whereas DS2005 was able to maintain a clean, shiny surface without change up to 150 units.