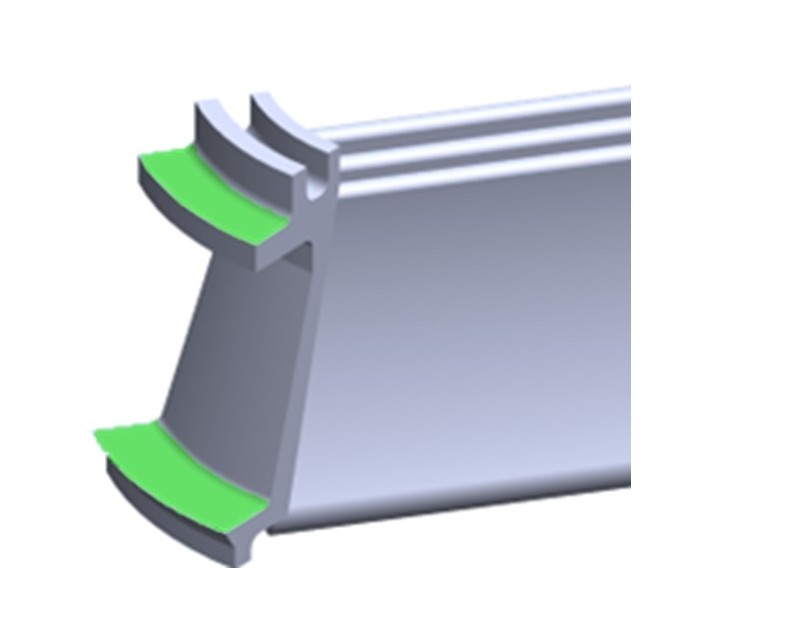

NTK JRF Cutter – Gas turbine component – SX3

NTK JRF Cutter - Gas turbine component - SX3

By combining a negative insert with higher cutting-edge strength, we achieve stable machining and extend tool life to 3 times longer than competitors. Productivity has improved by 1.3 times. Furthermore, adopting double-sided negative inserts contributes to reducing tool costs.

Share

| Industry | Oil & Gas |

|---|---|

| Component | Gas Turbine Components |

| Material ISO code |

|

| Work material | Inconel718 |

| Machine(spindle type) | Machining Center |

| Tool family | Milling |

| Tool category | Slotting |

| Product name | JRF Cutter |

| TSR No. | 5475M |

Tool

| Tungaloy - NTK | Competitor | |

|---|---|---|

| Body | JRFMH025E250R04 | Cutter |

| Number of teeth | 4 | 3 |

| Insert | RNGF060400E-HNF | RPGN060300E |

| Grade | SX3 | Ceramic Insert |

Tool life

| Tungaloy - NTK | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 6 | 2 |

Cutting conditions

| Tungaloy - NTK | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 903 | 903 |

| Feed per tooth f/z (mm/t) | 0.03 | 0.03 |

| Feed speed Vf (mm/min) | 1380 | 1035 |

| Depth of cut ap (mm) | 1 | 0.5 |

| Coolant | DRY | DRY |