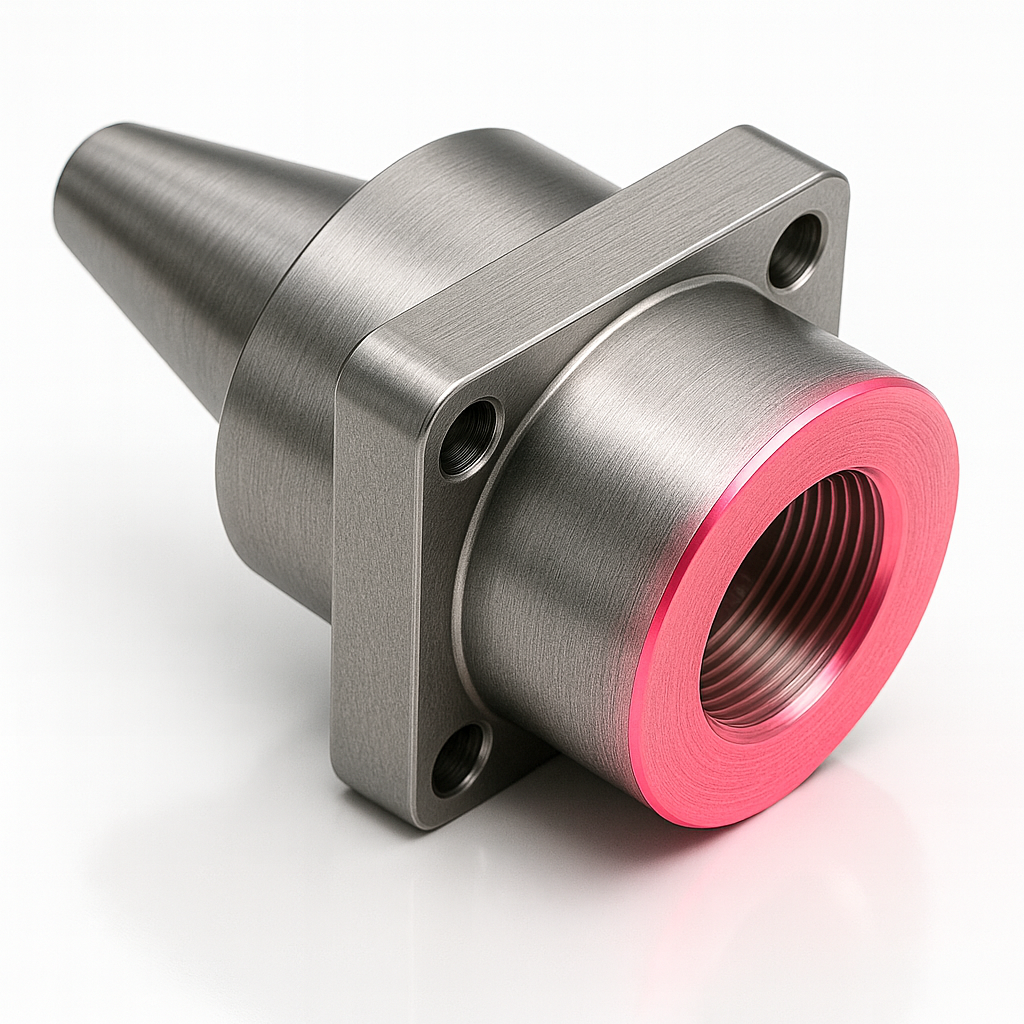

TetraForce-Cut – nozzle cylinder – AH6235

IMPROVE TOOL LIFE

In parting-off operations for SUJ2 nozzle cylinders on a Swiss lathe, the previous tool struggled with edge chipping and unstable cutting position, leading to inconsistent tool life and surface quality.

By adopting Tungaloy’s TetraForce-Cut with grade AH6235, known for its robust clamping structure and stable cutting performance, the machining process achieved significantly improved reliability without tool position deviation.

As a result, the number of parts processed per cutting edge increased from 3,000 to 4,000, delivering a tool life improvement of over 30%.

Share

| Industry | Automotive |

|---|---|

| Component | nozzle cylinder |

| Material ISO code |

|

| Work material | SUJ2 |

| Machine(spindle type) | Swiss Lathe |

| Tool family | Grooving |

| Tool category | Parting off |

| Product name | TetraForce-Cut |

| TSR No. | 115374G |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | STCL1212-27-CHP | 12x12 shank |

| Insert | TCS27-200-020 | 5 corner insert |

| Edges par insert | 4 | 5 |

| Cutting width | 3.4 | 3.4 |

| Grade | AH6235 | PVD grade |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 4000 | 3000 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 105 | 105 |

| Feed f (mm/rev) | 0.05 | 0.05 |

| Depth (mm) | 3.4 | 3.4 |

| Coolant | External | External |