IMPROVE PRODUCTIVITY

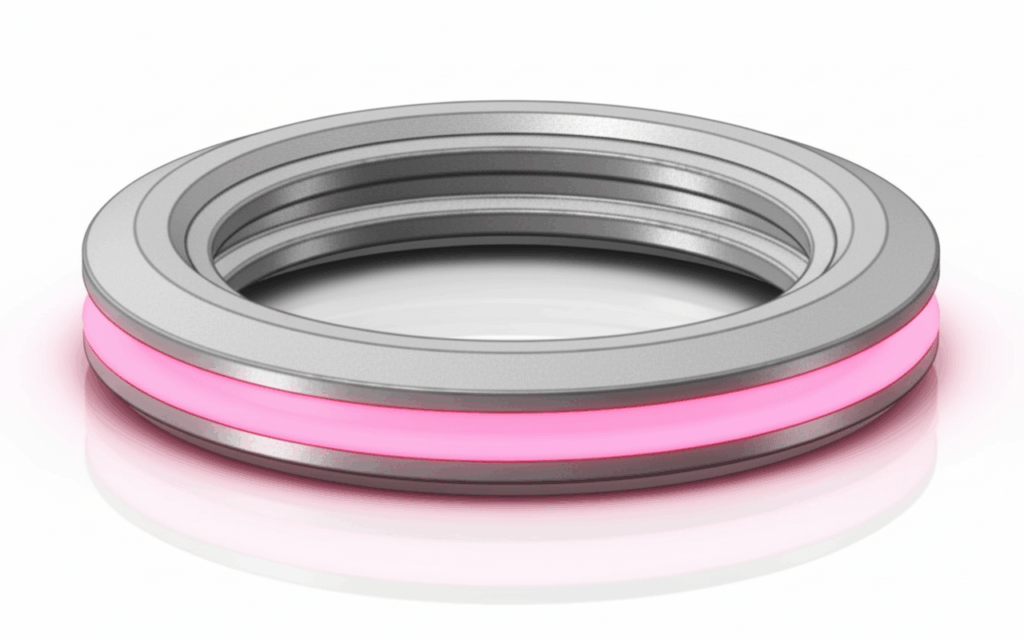

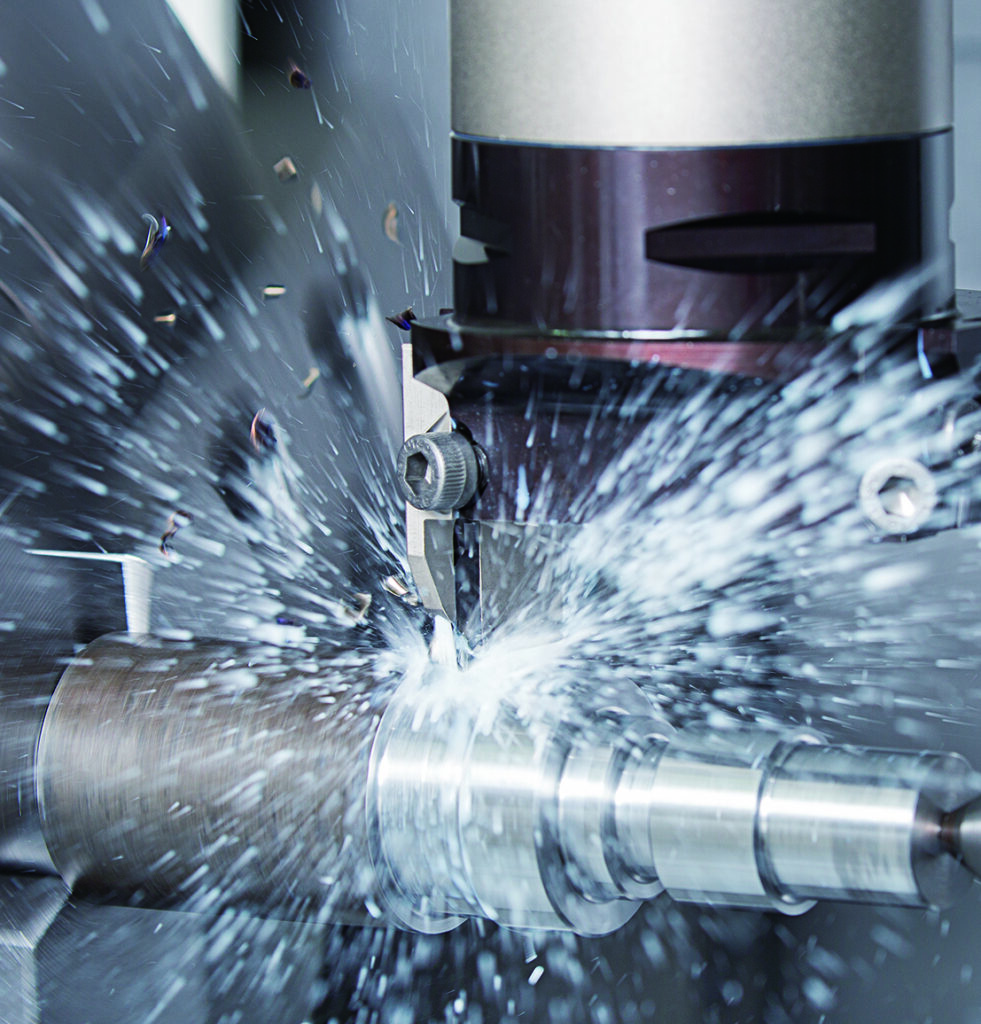

In grooving operations on Ti6Al4V gas generating seals for the aerospace industry, the previous tool struggled with poor chip control, leading to frequent tool damage and reduced productivity on vertical CNC lathes.

By adopting Tungaloy's TungCut system with AH8005 grade, which features a hard, wear-resistant PVD coating optimized for high-speed cutting and superalloy applications, the user achieved stable chip formation and dramatically minimized the risk of tool breakage.

This resulted in productivity gains of over 220%, with consistent chip control even at higher feeds, enabling nearly double the machining efficiency compared to the previous setup.