IMPROVE TOOL LIFE

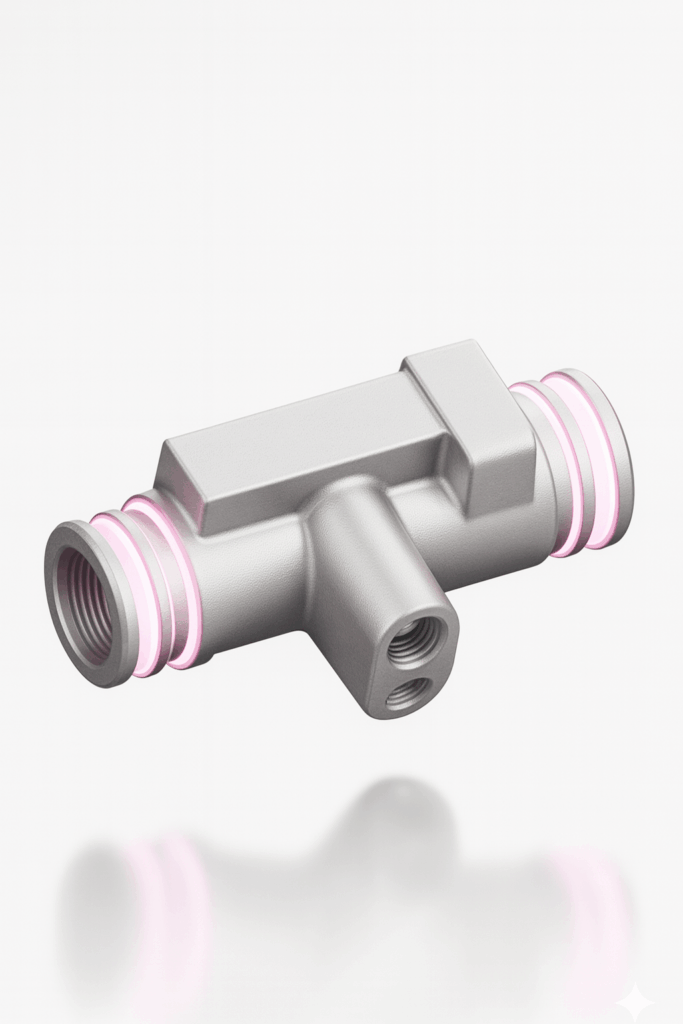

In external grooving of FCD500 valve housings on a CNC lathe, the previous tool offered limited tool life, requiring frequent insert changes and disrupting production efficiency.

By introducing Tungaloy's TungCut system with the AH8005 grade—engineered for superior wear and fracture resistance in cast iron applications—the machining process achieved dramatic improvement in stability and tool longevity.

As a result, tool life increased nearly fivefold, with the new solution delivering up to 680 parts per edge compared to just 140 with the conventional tool. This substantial extension minimizes downtime, optimizes throughput, and supports highly cost-efficient, stable production for automotive components.