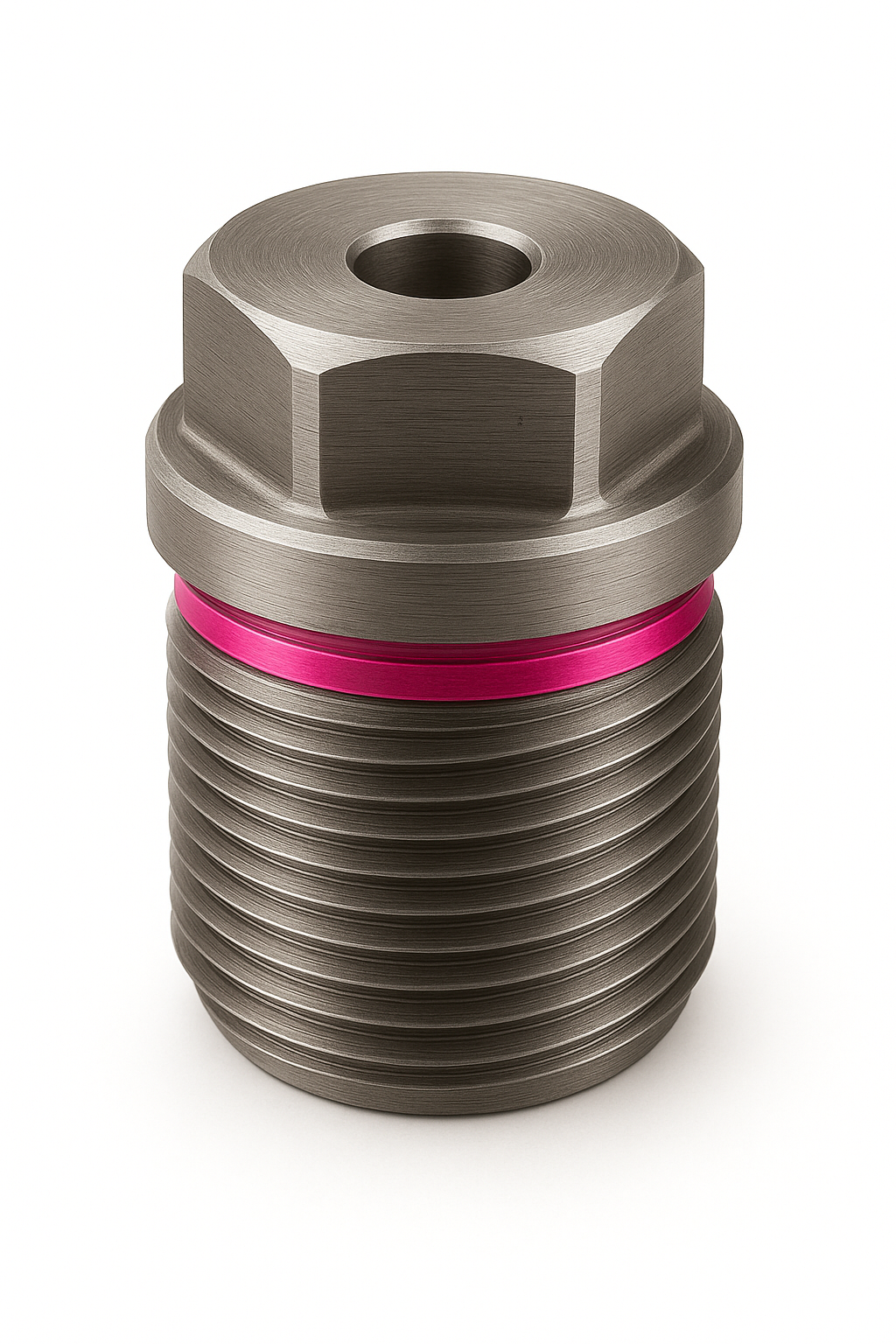

TetraMini-Cut – plug – AH725

IMPROVE TOOL LIFE

For external grooving of S45C steel plugs on a CNC lathe, the previous tool was limited by tool life and stability concerns.

By implementing TetraMini-Cut with AH725 grade, known for its durability and consistent performance in steel applications, the user achieved notably improved tool longevity and reliable machining.

The number of parts produced per cutting edge increased from 4,000 to 5,000, representing a 25% boost in tool life and establishing a stable process suitable for wider adoption.

Share

| Industry | Automotive |

|---|---|

| Component | plug |

| Material ISO code |

|

| Work material | S 45 C |

| Machine(spindle type) | CNC Lathe |

| Tool family | Grooving |

| Tool category | External grooving |

| Product name | TetraMini-Cut |

| TSR No. | 121621G |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | STCR1616X18 | 16x16 shank |

| Insert | TCP18R200-010 | 3 corner insert |

| Edges par insert | 4 | 3 |

| Cutting width | 2 | 2 |

| Grade | AH725 | PVD grade |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 5000 | 4000 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 94 | 94 |

| Feed f (mm/rev) | 0.05 | 0.05 |

| Depth (mm) | 1 | 1 |

| Coolant | External | External |