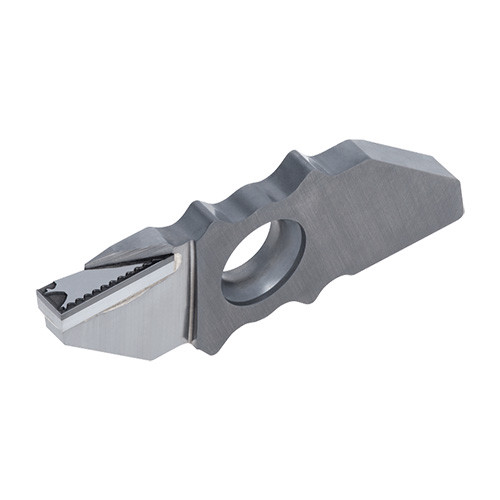

DuoJust-Cut – pneumatic components – DX110

IMPROVE TOOL MANAGEMENT

In parting-off of non-ferrous materials on a CNC lathe, the previous approach required locally brazed PCD solutions, resulting in additional setup time and complexity.

By introducing DuoJust-Cut with DX110 grade inserts, the process achieved excellent machining performance and eliminated the need for local brazing. As a result, productivity increased significantly, with 10,000 parts machined per edge while ensuring process reliability and stability.

This demonstrates the versatility and efficiency of DuoJust-Cut, especially for demanding engineering applications.

Share

| Industry | Engineering |

|---|---|

| Component | pneumatic components |

| Material ISO code |

|

| Work material | A5052 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Grooving |

| Tool category | Parting off |

| Product name | DuoJust-Cut |

| TSR No. | 121178G |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | JSXXR083-S | Blazed PCD tool |

| Insert | JXDX12R20F | |

| Edges par insert | 1 | 1 |

| Cutting width | 1.2 | 1.2 |

| Grade | DX110 | PCD |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 10000 | 10000 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 650 | 650 |

| Feed f (mm/rev) | 0.1 | 0.1 |

| Coolant | Dry | Dry |