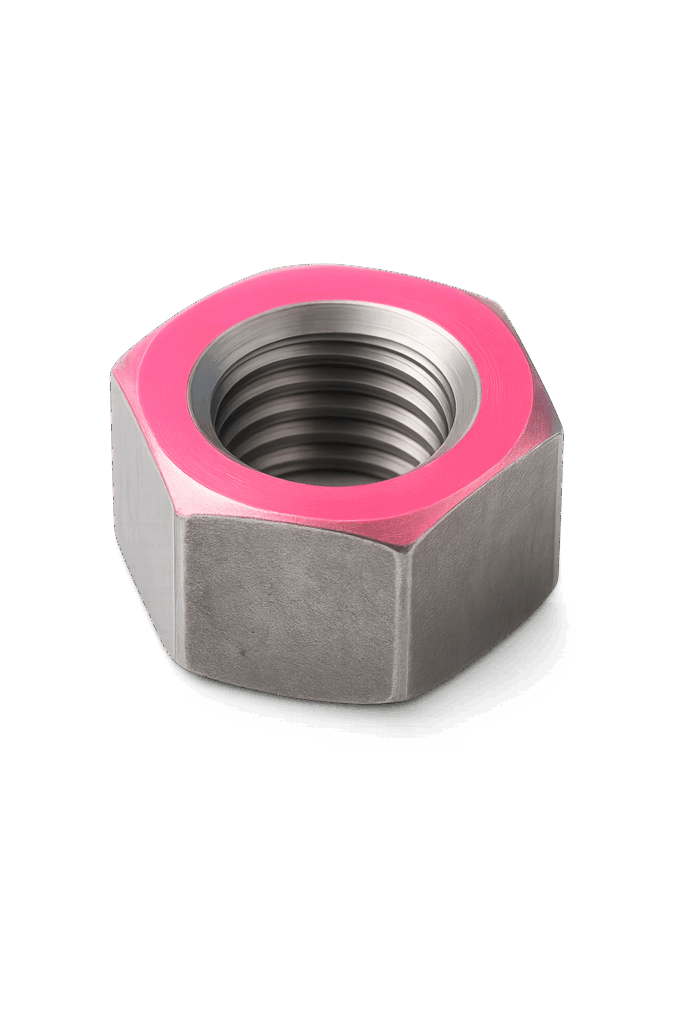

TungCut – nut – AH6235

IMPROVE TOOL LIFE

During pating off of SUS304 nuts on a CNC lathe, the previous tool offered moderate performance but was limited by insufficient tool life, especially when compared to competing solutions.

By adopting TungCut with the AH6235 grade—featuring a high-hardness, titanium-rich nano PVD coating designed for wear and fracture resistance in stainless steel—stable performance and extended edge durability were achieved.

As a result, the number of parts produced per edge increased by 20%, demonstrating clear tool life improvement over the conventional solution.

Share

| Industry | Engineering |

|---|---|

| Component | Nut |

| Material ISO code |

|

| Work material | SUS304 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Grooving |

| Tool category | Parting off |

| Product name | TungCut |

| TSR No. | 120233G |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | CTER2525-3T12 | 25x25 shank |

| Insert | DGS3-020 | 2 corner insert |

| Edges par insert | 2 | 2 |

| Cutting width | 3 | 3 |

| Grade | AH6235 | PVD grade |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 180 | 150 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 80 | 80 |

| Feed f (mm/rev) | 0.03 | 0.03 |

| Depth (mm) | 10 | 10 |

| Coolant | External | External |