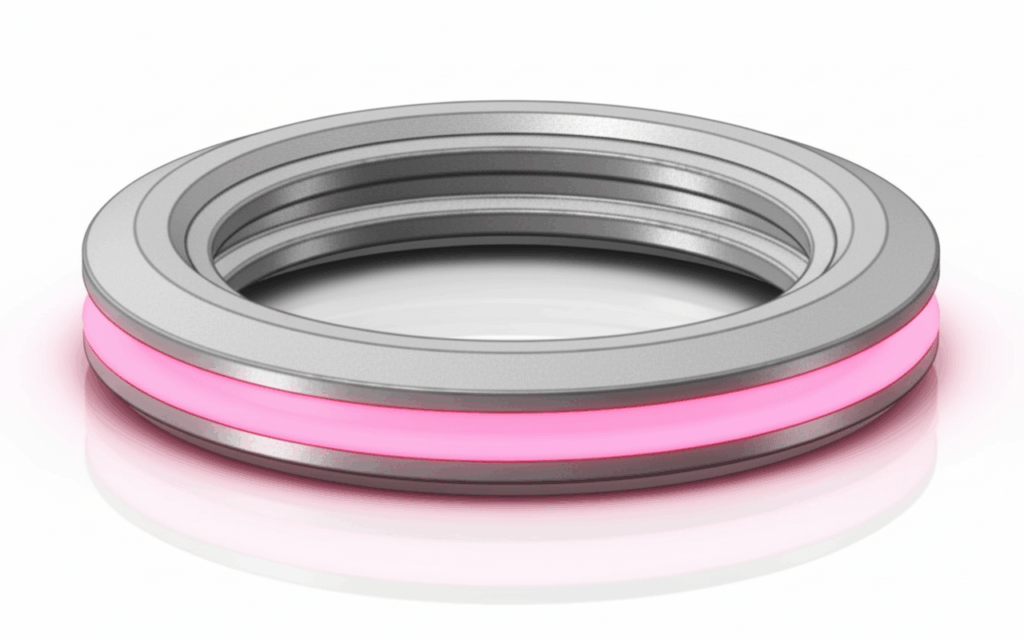

TetraMini-Cut – camera adjustment ring – AH8005

IMPROVE TOOL LIFE

For grooving operations on HPM38 camera adjustment rings using a CNC lathe, the previous tool suffered from significant burr formation and extremely short tool life, making stable machining difficult.

By implementing Tungaloy’s TetraMini-Cut with wear-resistant AH8005 grade—engineered for hardened materials and featuring a high-hardness PVD coating—the process achieved excellent resistance to built-up edge and stable performance.

As a result, tool life improved dramatically, with the number of parts processed per edge increasing from 5 to 120, representing a 24-fold increase. This enabled greater process reliability and a substantial reduction in tool change frequency.

Share

| Industry | Engineering |

|---|---|

| Component | camera adjustment ring |

| Material ISO code |

|

| Work material | HPM38 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Grooving |

| Tool category | External grooving |

| Product name | TetraMini-Cut |

| TSR No. | 122628G |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | STCR2525Z18 | 25x25 shank |

| Insert | TCG18R100-010 | 3 corner insert |

| Edges par insert | 4 | 3 |

| Cutting width | 1 | 1 |

| Grade | AH8005 | PVD grade |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 120 | 5 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 50 | 50 |

| Feed f (mm/rev) | 0.03 | 0.03 |

| Depth (mm) | 1 | 1 |

| Coolant | External | External |