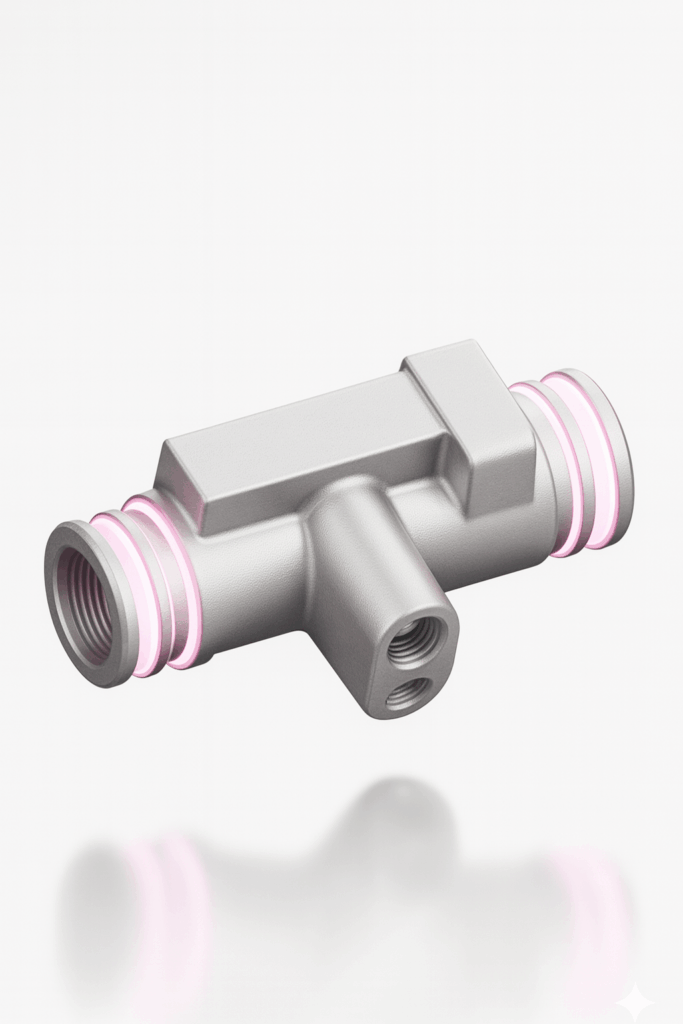

TungCut – construction machinery parts – AH7025

IMPROVE TOOL LIFE

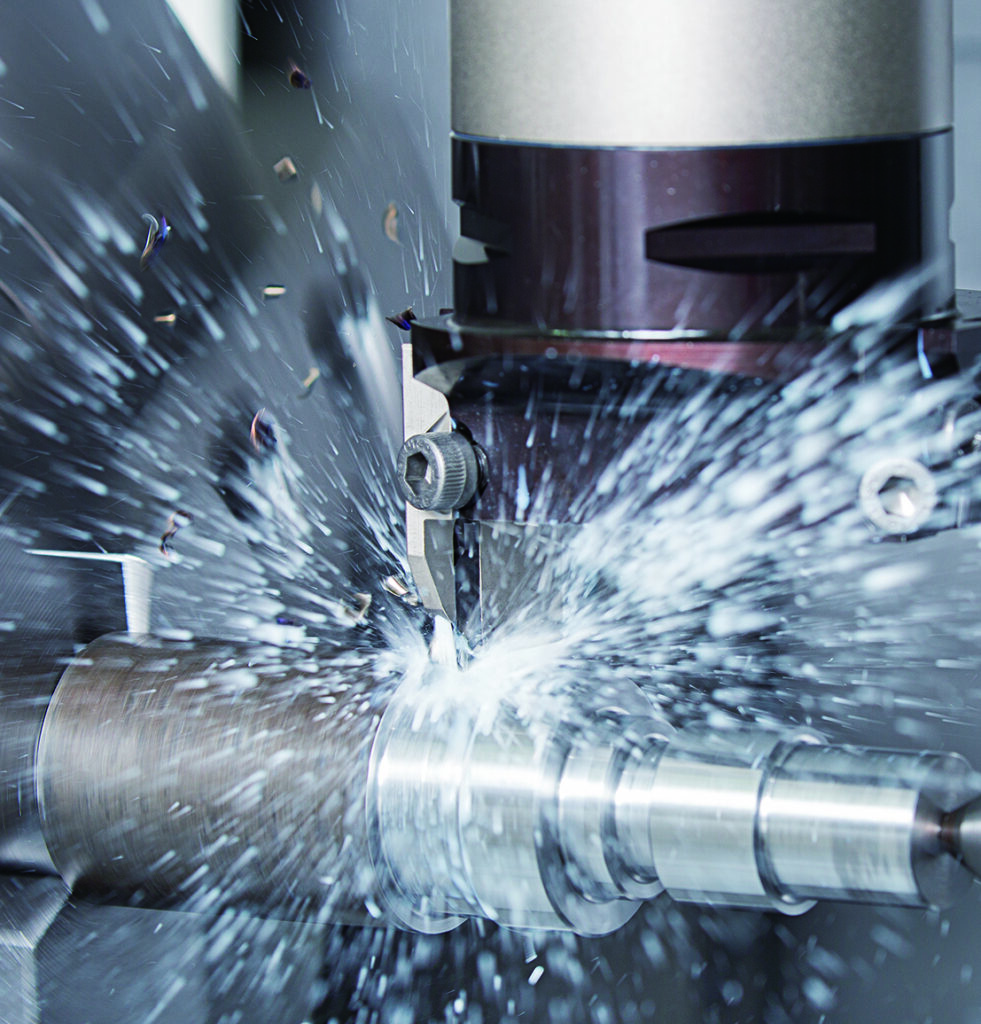

In external grooving of S45CF construction machinery parts on a CNC lathe, the previous tool's limited tool life was a concern, leading to frequent insert changes.

By adopting Tungaloy’s TungCut system equipped with the AH7025 grade insert, which features a nano-multilayer PVD coating for superior wear and chipping resistance, the customer achieved much greater edge durability.

This upgrade extended tool life to over 1,000 parts per cutting edge—approximately a 67% improvement compared with the prior solution—significantly reducing downtime and boosting efficiency in production.

Share

| Industry | Engineering |

|---|---|

| Component | Construction machinery parts |

| Material ISO code |

|

| Work material | S45CF |

| Machine(spindle type) | CNC Lathe |

| Tool family | Grooving |

| Tool category | Internal grooving |

| Product name | TungCut |

| TSR No. | 122594G |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | CAER-3T16-CHP | 25x25 shank |

| Shank | CHSR2525-CHP | |

| Insert | DGM3-020 | 2 corner insert |

| Edges par insert | 2 | 2 |

| Cutting width | 3 | 3 |

| Grade | AH7025 | PVD grade |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 1000 | 600 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 100 | 100 |

| Feed f (mm/rev) | 0.1 | 0.1 |

| Depth (mm) | 0.9 | 0.9 |

| Coolant | Internal | External |