IMPROVE PRODUCTIVITY AND TOOL LIFE

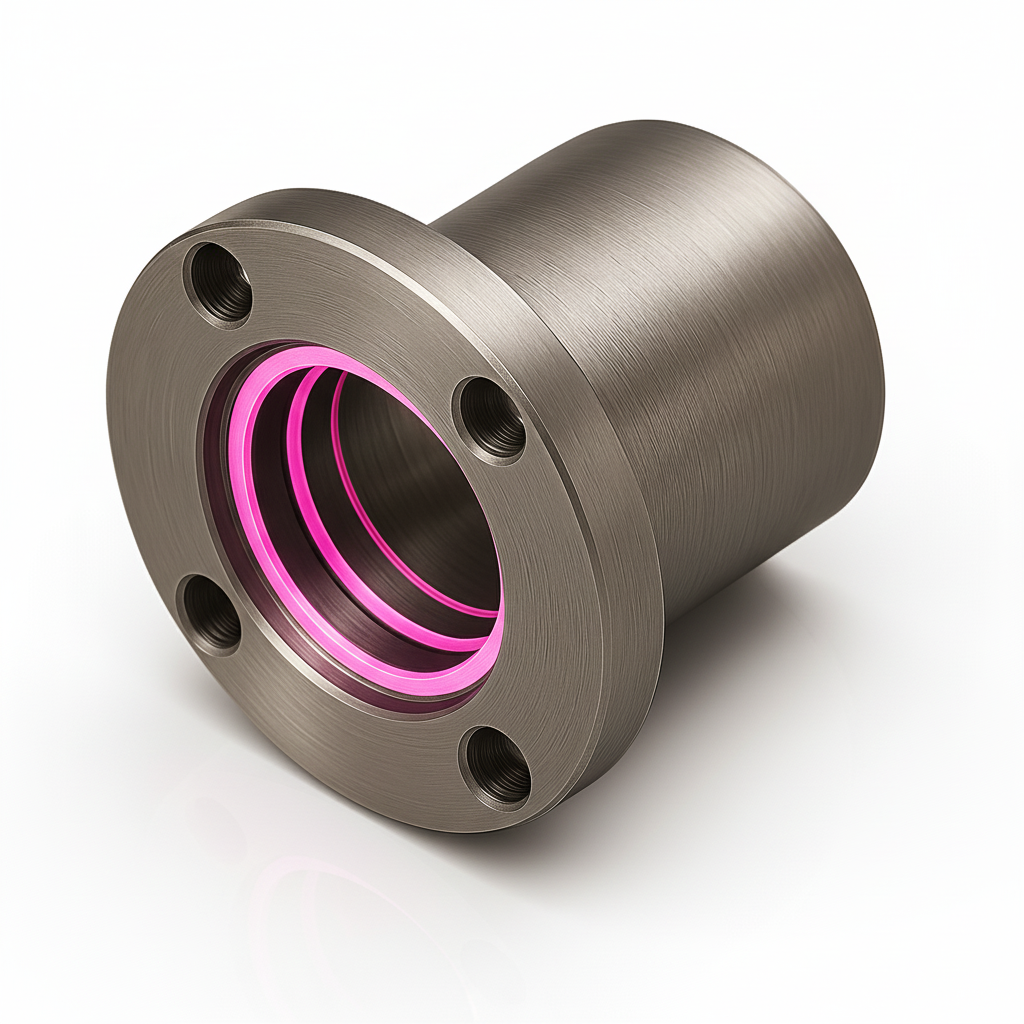

In the internal grooving of SUS304 machine parts on a CNC lathe, the previous tool struggled with frequent edge chipping and minimal tool life, producing only one part per cutting edge.

By adopting Tungaloy’s TungCut system with the DGM3-020 insert in AH6235 grade, designed for stable and wear-resistant performance on stainless steel, the operation experienced a significant boost in both productivity and durability.

Tool life was extended to three parts per edge with no chipping issues, achieving a 150% productivity improvement and 300% increase in tool life compared to the previous solution. These results led to the formal adoption of the TungCut tool for this demanding application.