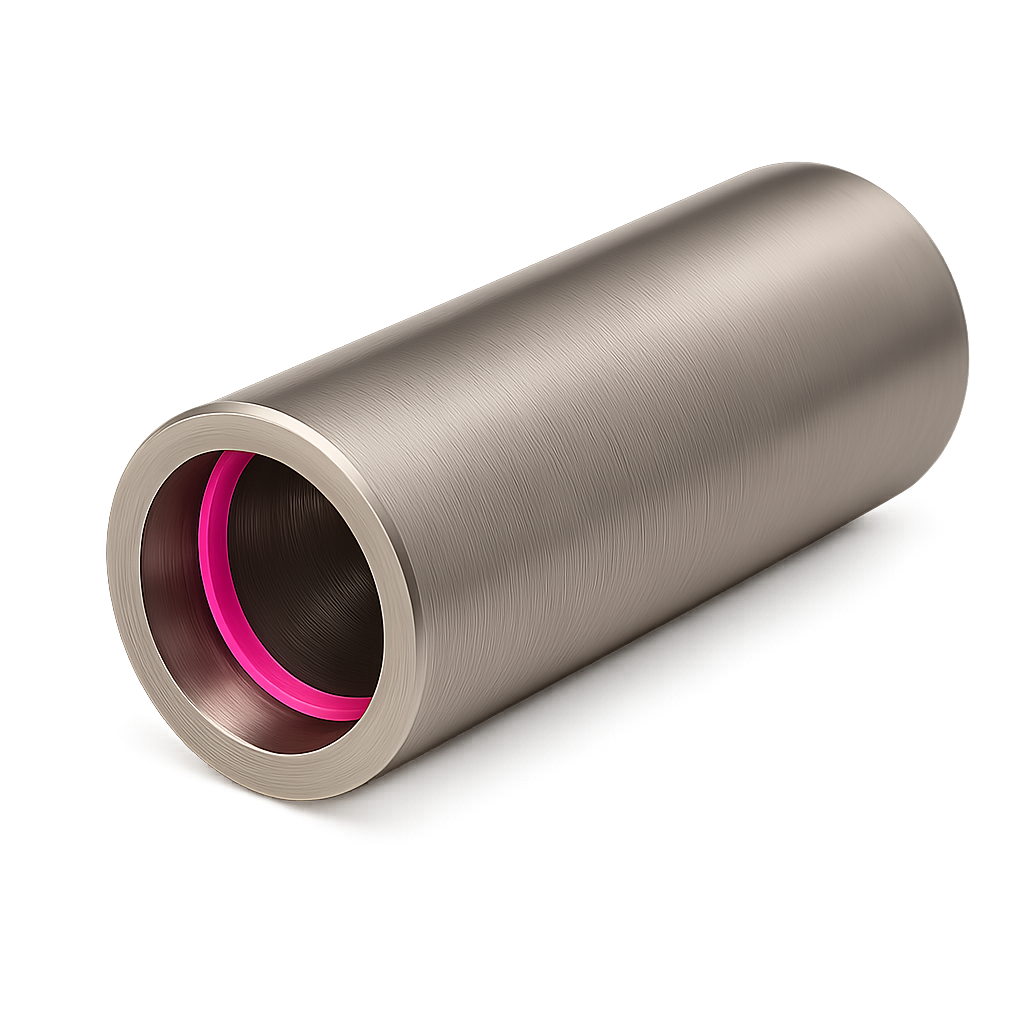

AddInternalCut – body – AH725

IMPROVE TOOL COST

In internal grooving operations on SUS304 components, the previous tool suffered from poor chip control, making stable machining difficult under the existing conditions.

By adopting Tungaloy’s AddInternalCut with grade AH725—a solution engineered for stainless steel and renowned for its reliable chip evacuation—the customer achieved consistently smooth chip flow even at unchanged cutting parameters.

As a result, the process experienced improved operational stability and reduced risk of chip-related troubles, prompting a full conversion to AddInternalCut.

Share

| Industry | Engineering |

|---|---|

| Component | body |

| Material ISO code |

|

| Work material | SUS304 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Grooving |

| Tool category | Internal grooving |

| Product name | AddInternalCut |

| TSR No. | 122388G |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | E12K-STCIR10-D150 | Φ10 shank |

| Insert | TCIG10-122-008 | 1 corner insert |

| Edges par insert | 4 | 1 |

| Cutting width | 1.22 | 1.25 |

| Grade | AH725 | PVD grade |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 10 | 10 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 20 | 20 |

| Feed f (mm/rev) | 0.05 | 0.05 |

| Depth (mm) | 2 | 2 |

| Coolant | External | External |