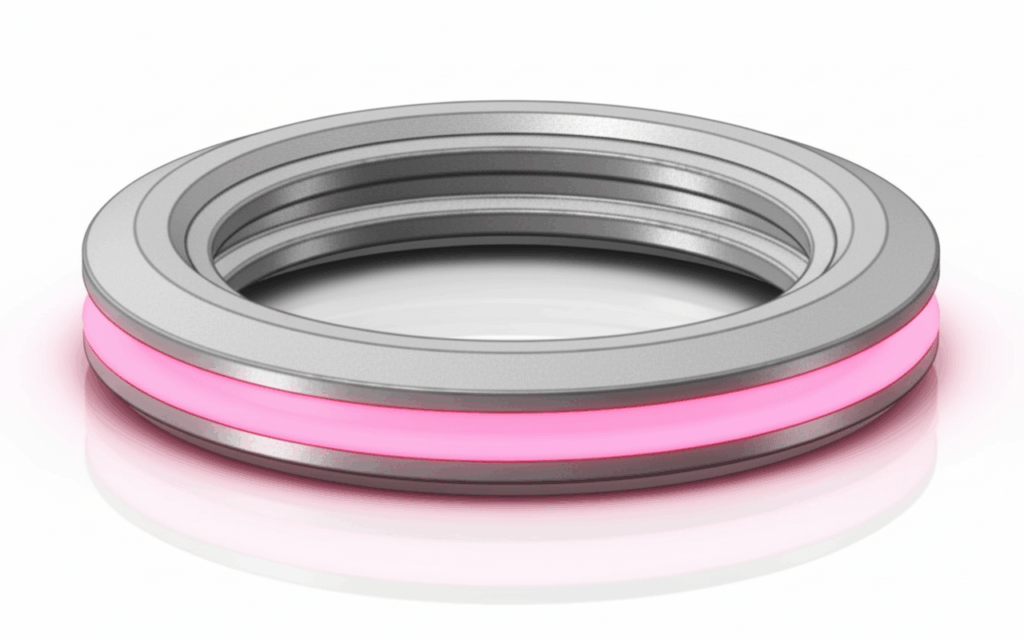

TungCut – roller – NS9530

IMPROVE SURFACE QUALITY

In the external grooving of S45C rollers on a CNC lathe, the user required a tool that could deliver precise finishing and stable performance on a new workpiece. By adopting Tungaloy’s TungCut system with NS9530 grade inserts, known for their remarkable fracture and wear resistance in steel applications, reliable and consistent machining was achieved.

As a result, the tool provided both excellent stability and long tool life, supporting the user’s productivity goals and earning adoption for the new part.

Share

| Industry | Engineering |

|---|---|

| Component | Roller |

| Material ISO code |

|

| Work material | S 45 C |

| Machine(spindle type) | CNC Lathe |

| Tool family | Grooving |

| Tool category | External grooving |

| Product name | TungCut |

| TSR No. | 122364G |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | CTER2020-3T09 | |

| Insert | DTX3-030 | |

| Edges par insert | 2 | |

| Cutting width | 3 | |

| Grade | NS9530 |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 200 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 300 | |

| Feed f (mm/rev) | 0.07 | |

| Depth (mm) | 0.2 | |

| Coolant | External |