TungCut -Aircraft parts- AH6235

IMPROVE TOOL LIFE

When machining the backside flange of aircraft parts made from Inconel 718, frequent insert failure and insufficient tool life were challenges during heavy interrupted grooving operations.

By introducing TungCut with grade AH6235—engineered for superior wear and fracture resistance on demanding superalloys—process stability was significantly improved.

As a result, tool life doubled compared to the previous solution, reducing insert changes and contributing to higher operational efficiency.

Share

| Industry | Heavy |

|---|---|

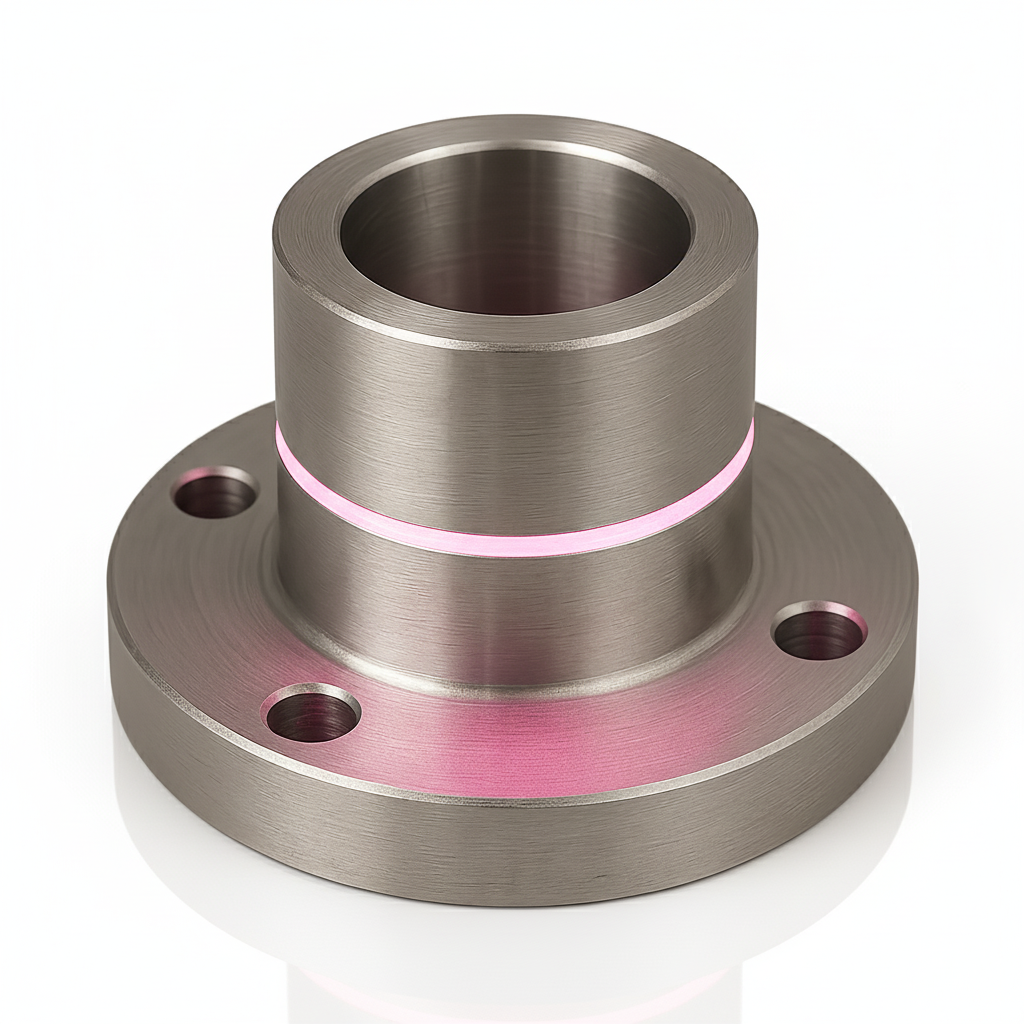

| Component | Aircraft parts |

| Material ISO code |

|

| Work material | Inconel718 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Grooving |

| Tool category | External grooving |

| Product name | TungCut |

| TSR No. | 122337G |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | CTER2525-6T16 | 25x25 shank |

| Insert | DTE6-080 | 2 corner insert |

| Edges par insert | 2 | 2 |

| Cutting width | 6 | 6 |

| Grade | AH6235 | PVD grade |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 1 | 0.5 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 20 | 20 |

| Feed f (mm/rev) | 0.1 | 0.1 |

| Depth (mm) | 10 | 10 |

| Coolant | External | External |