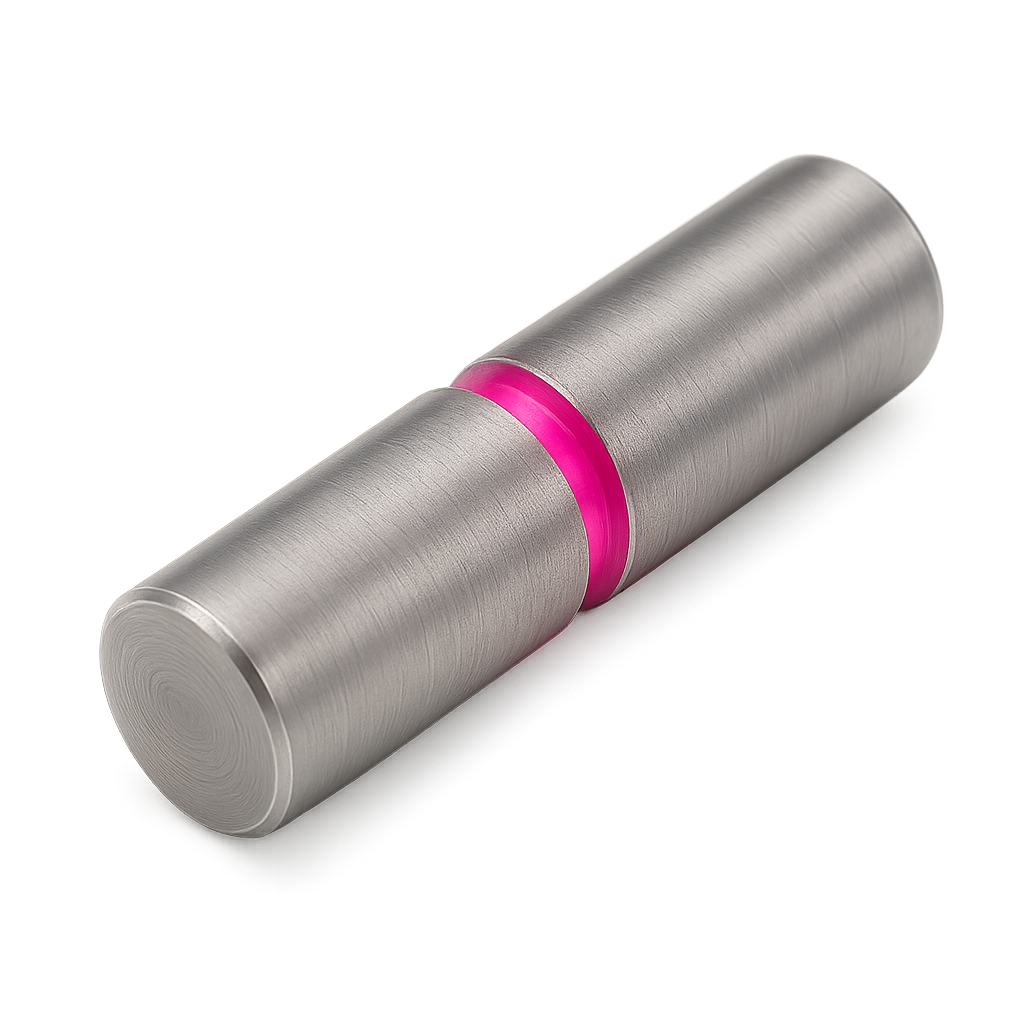

TetraMini-Cut – Shaft pin – AH6235

IMPROVE TOOL LIFE

In external grooving of SS400 shaft pins, the previous tool often caused scratches on the groove width, resulting in quality issues and unsatisfactory tool life. By adopting Tungaloy's TetraMini-Cut with the wear-resistant AH6235 grade, the process achieved stable machining without surface defects, thanks to the tool's rigid clamping and precise insert geometry.

As a result, the number of parts produced per cutting edge increased from 600 to 800, delivering a 33% improvement in tool life and ensuring consistent surface quality.

Share

| Industry | Engineering |

|---|---|

| Component | Shaft pin |

| Material ISO code |

|

| Work material | SS400 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Grooving |

| Tool category | External grooving |

| Product name | TetraMini-Cut |

| TSR No. | 122120G |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | STCR2525Z18 | 25x25 shank |

| Insert | TCG18R125-010 | 2 corner insert |

| Edges par insert | 4 | 2 |

| Cutting width | 1.25 | 1.25 |

| Grade | AH6235 | PVD grade |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 800 | 600 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 40 | 40 |

| Feed f (mm/rev) | 0.05 | 0.05 |

| Depth (mm) | 0.5 | 0.5 |

| Coolant | External | External |