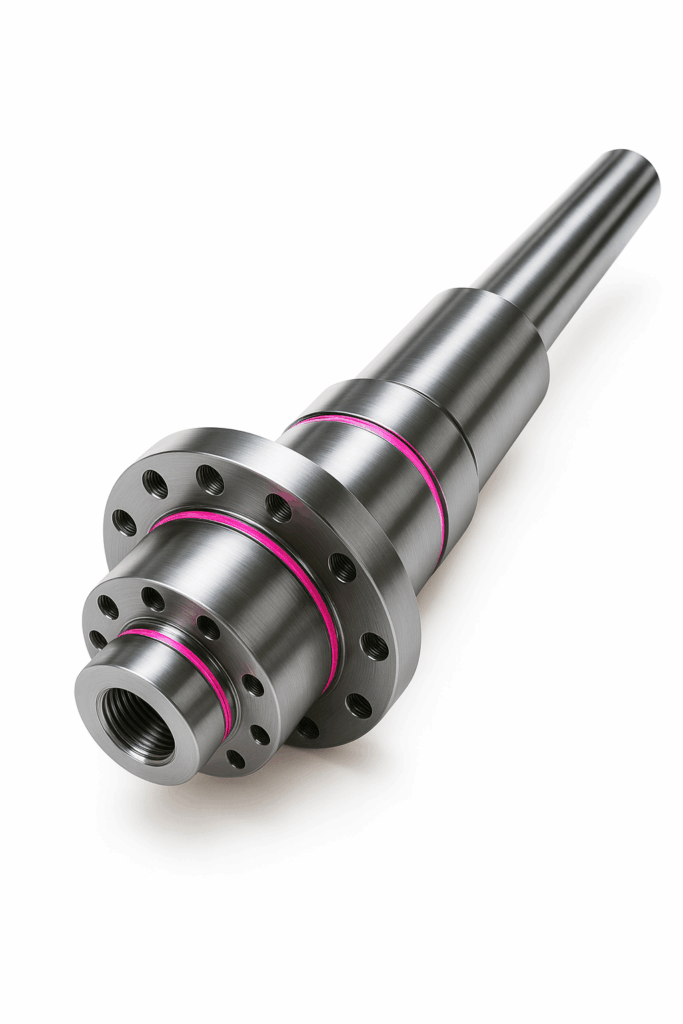

TetraMini-Cut – shaft – AH7025

IMPROVE TOOL COST

In external grooving of S45C shaft components for machine production, the conventional tool was prone to chatter and offered only a limited number of cutting edges, which restricted efficiency.

By introducing Tungaloy’s TetraMini-Cut with grade AH7025, designed for rigidity and stable grooving,

the process achieved comparable tool life while effectively suppressing vibration. Additionally, the number of usable corners per insert doubled from two to four, providing greater cost efficiency and stable performance.

Share

| Industry | Machine production |

|---|---|

| Component | Shaft |

| Material ISO code |

|

| Work material | S 45 C |

| Machine(spindle type) | CNC Lathe |

| Tool family | Grooving |

| Tool category | External grooving |

| Product name | TetraMini-Cut |

| TSR No. | 121699G |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | C4STCR27050-18-CHP | C4 grooving tool |

| Insert | TCG18R200-020 | 2 corner insert |

| Edges par insert | 4 | 2 |

| Cutting width | 2.0 | 2.0 |

| Grade | AH7025 | PVD grade |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 700 | 700 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 100 | 100 |

| Feed f (mm/rev) | 0.08 | 0.08 |

| Depth (mm) | 2.5 | 2.5 |

| Coolant | Internal | Internal |