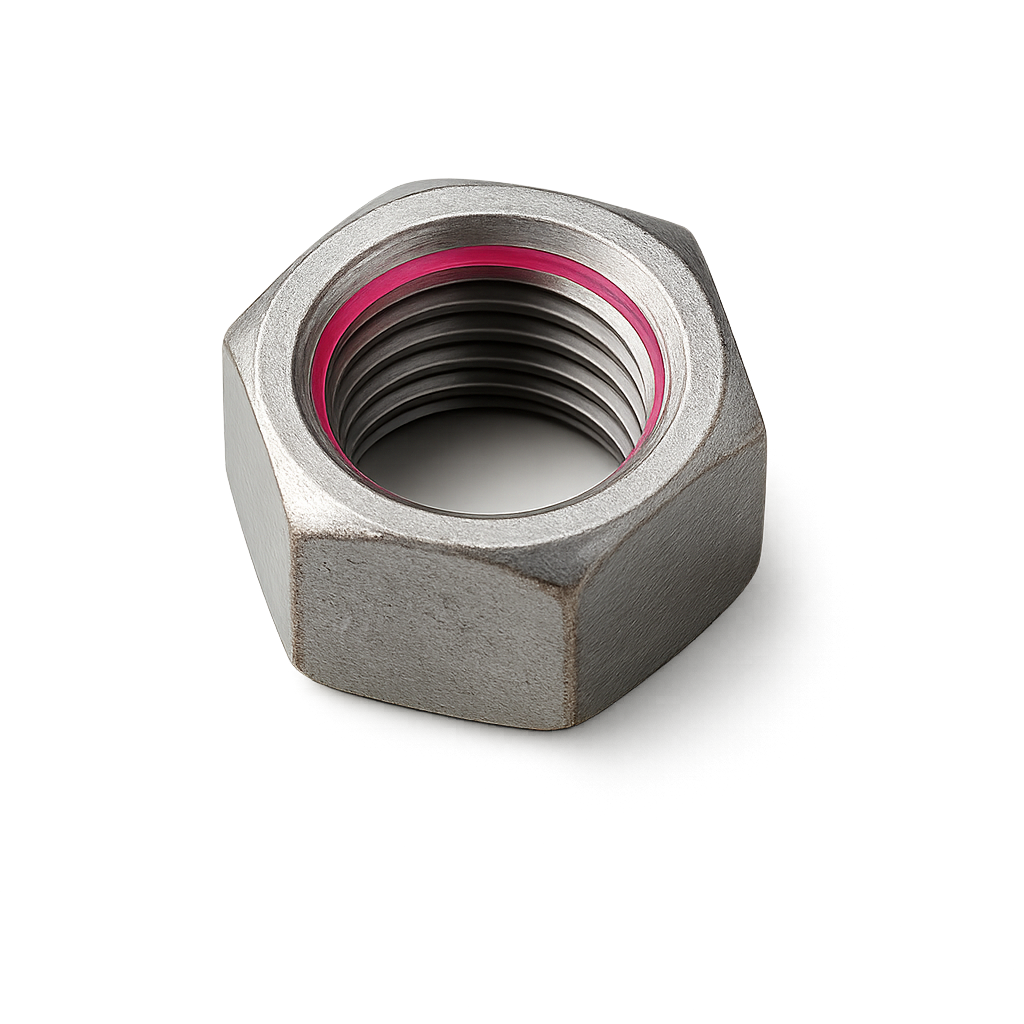

AddInternalCut – nut – AH725

IMPROVE TOOL LIFE

During internal grooving of SUS304 nuts on a CNC lathe, the previous solution struggled with insert chipping and limited tool life, restricting stable production.

By introducing AddInternalCut with AH725 grade—engineered for an excellent balance of wear and chipping resistance in stainless steel—the customer achieved stable processing with longer edge durability.

Tool life improved markedly, increasing from 500 to 600 parts per edge, while chip control remained on par with the previous tool. This allowed for reliable, consistent machining performance and reduced insert change frequency, supporting improved efficiency in nut production.

Share

| Industry | Automotive |

|---|---|

| Component | Nut |

| Material ISO code |

|

| Work material | SUS304 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Grooving |

| Tool category | Internal grooving |

| Product name | AddInternalCut |

| TSR No. | 121540G |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | E12K-STCIR10-D150 | Φ12 shank |

| Insert | TCIG10-200-010 | 2 corner insert |

| Edges par insert | 4 | 2 |

| Cutting width | 2 | 2 |

| Grade | AH725 | PVD grade |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 600 | 500 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 60 | 60 |

| Feed f (mm/rev) | 0.03 | 0.03 |

| Depth (mm) | 1.85 | 1.85 |

| Coolant | External | External |