SBN30-Brake Drum

Excellent machined surface quality

Chipping occurred after 200 workpieces when using a competitor’s product, resulting in a deteriorated surface finish. In contrast, SBN30, with its excellent fracture resistance, showed no chipping and maintained a good surface finish, thereby contributing to improved quality.

Share

| Industry | Automotive |

|---|---|

| Component | Brake Drum |

| Material ISO code |

|

| Work material | FC200 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | External turning |

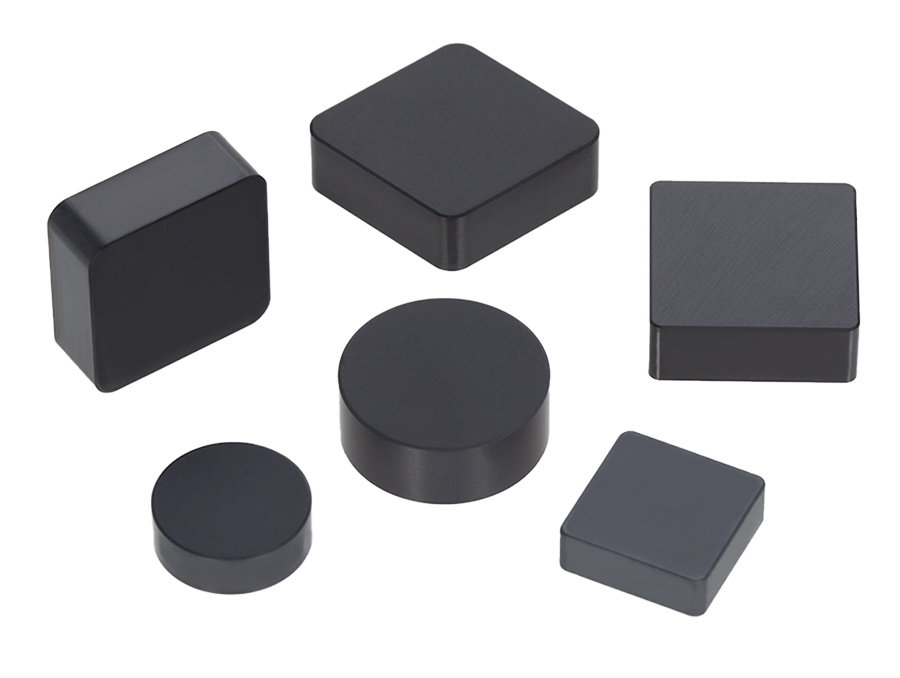

| Product name | SBN30 |

| TSR No. | 5411T |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | KM Special Holder | KM Special Holder |

| Insert | S-SNUN120416HU | SNMN120416 |

| Edges par insert | 8 | 8 |

| Grade | SBN30 | Solid CBN K10 |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 200 | 150 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 1000 | 1000 |

| Feed f (mm/rev) | 0.25 | 0.25 |

| Depth of cut ap (mm) | 2.5 | 2.5 |

| Coolant | Wet | Wet |