TungTap ‐ Tool holder – GB070

IMPROVED TOOL LIFE

The grade GB060, which adopts a wear-resistant TiCN coating, enabled stable machining without breakage even in high-hardness steel. As a result, tool life was improved by 1.5 times.

Share

| Industry | Engineering |

|---|---|

| Component | Toolholder |

| Material ISO code |

|

| Work material | SNCM439 |

| Material hardness | 45HRC |

| Machine(spindle type) | 5-axis Machining Center |

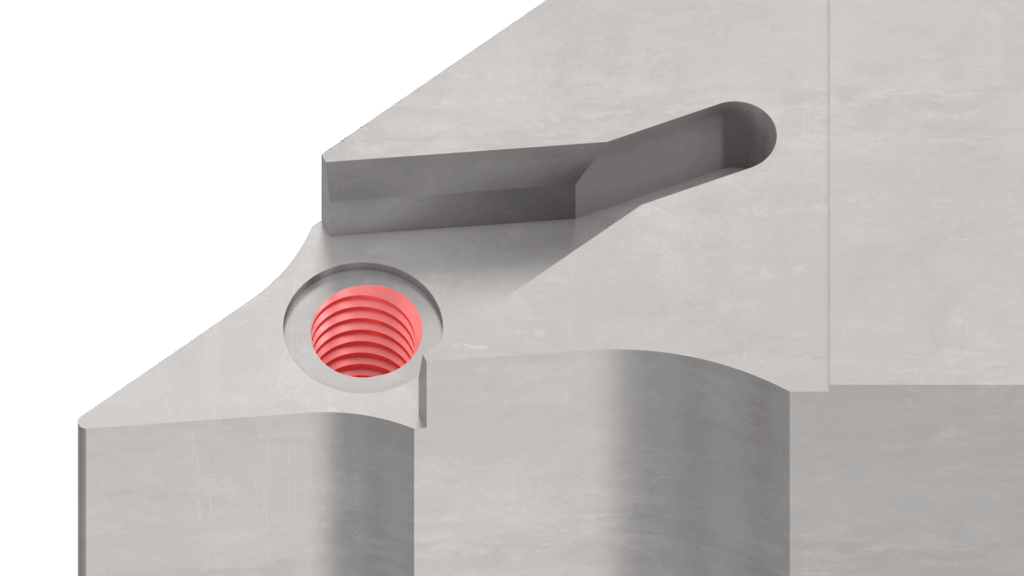

| Tool family | Holemaking |

| Tool category | Tapping |

| Product name | TungTap |

| TSR No. | 5402D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TP-M3.5X0.6-DNBH GB070 | M3.5x0.6 tap |

| Grade | GB070 | TiN + HSSE |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Number of workpieces (pcs/insert) | 300 | 200 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | M3.5x0.6 | M3.5x0.6 |

| Pilot hole diameter (mm) | 2.9 | 2.9 |

| Hole depth H (mm) | 5 | 5 |

| Cutting speed V/c (m/min) | 8 | 8 |

| Feed f (mm/rev) | 0.6 | 0.6 |

| Feed speed Vf (mm/min) | 436.8 | 436.8 |

| Coolant | Wet, external | Wet, external |