VariableMeister- Ball screw nut- AH725

IMPROVED TOOL LIFE

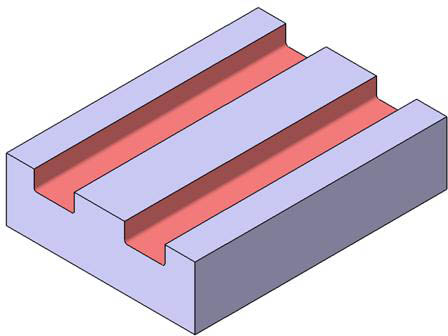

In the slot finishing process of ball screw nuts, a competitor’s general-purpose 2xDC end mill had been used previously. By switching to the VariableMeister short type 1xDC end mill, surface finish accuracy improved and became more consistent. Tool life was also extended by 1.4 times.

The VariableMeister was adopted; however, the customer continues testing with the aim of further improving machining efficiency.

Share

| Industry | Machine Tool Builders |

|---|---|

| Component | Ball Screw nut |

| Material ISO code |

|

| Work material | SCM415 |

| Machine(spindle type) | Vertical Machining Center Small(#30,HSK40) |

| Tool family | Milling |

| Tool category | Shoulder milling |

| Product name | VariableMeister |

| TSR No. | 5396M |

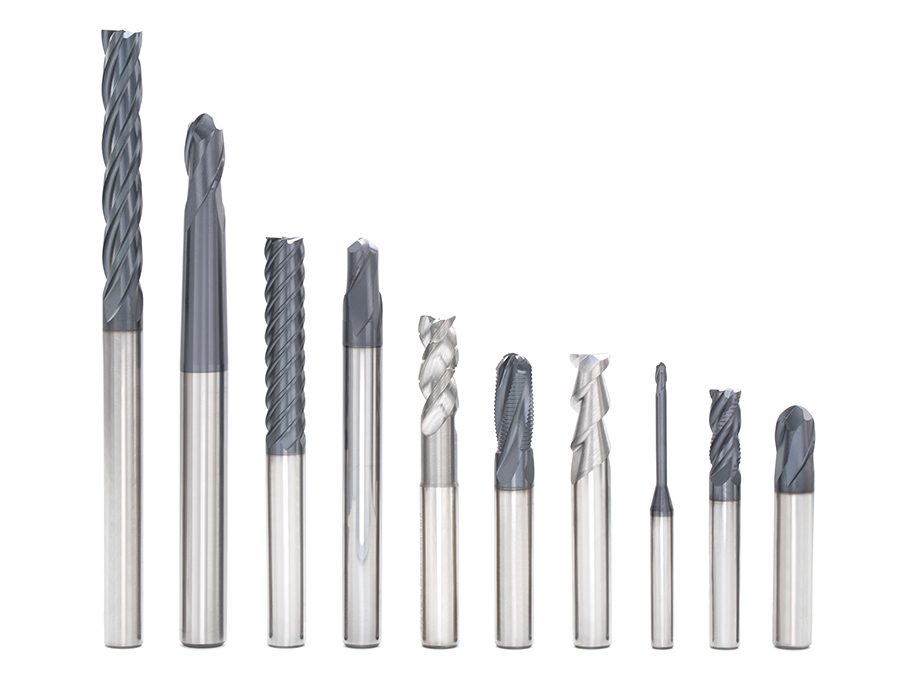

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TEC060H4S-06C06CFR02E50 | |

| Number of teeth | 4 | 4 |

| Cutting diameter | 6 | 6 |

| Grade | AH725 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 100 | 100 |

| Feed per tooth f/z (mm/t) | 0.02 | 0.02 |

| Feed speed Vf (mm/min) | 424 | 424 |

| Depth of cut ap (mm) | 5 | 5 |

| Width of cut ae (mm) | 0.1 | 0.1 |

| Coolant | External | External |