AddForceCut – valve – AH7025

IMPROVE PRODUCTIVITY

In external grooving of SS400 valves on a CNC lathe, the previous tool encountered significant vibration and productivity limitations at higher feed rates, especially with deep parting operations.

By introducing Tungaloy’s AddForceCut with the AH7025 grade, featuring a high-rigidity self-clamping system and excellent wear resistance, stable and chatter-free machining was achieved even at feed rates up to 0.15 mm/rev.

As a result, productivity was boosted by 300% compared to the previous solution, allowing for efficient and reliable processing across various part sizes and work materials.

Share

| Industry | Engineering |

|---|---|

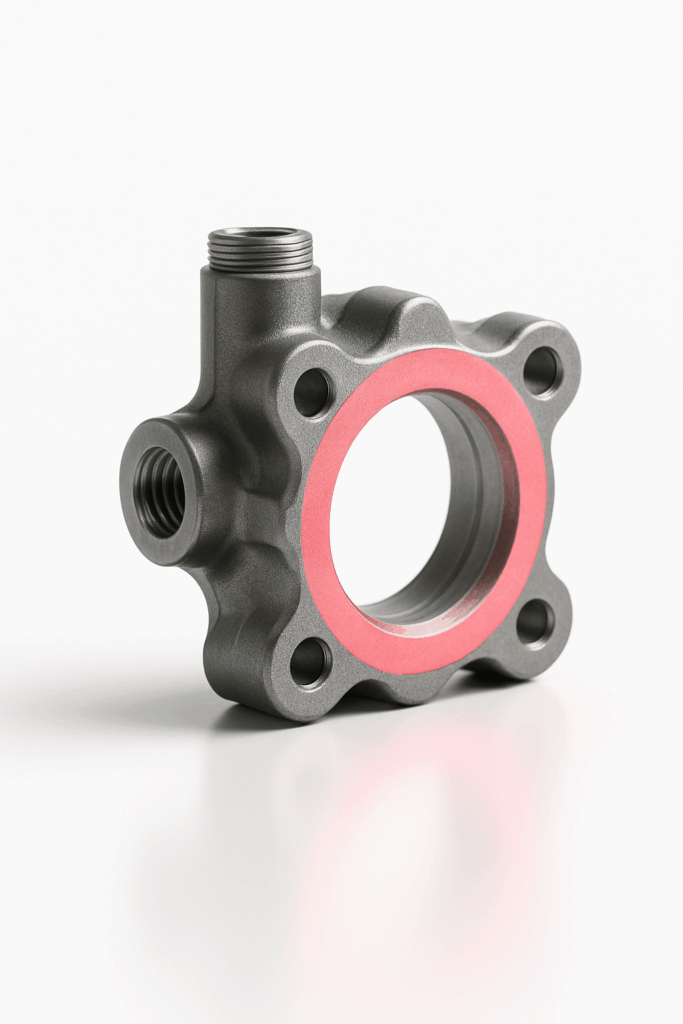

| Component | Valve |

| Material ISO code |

|

| Work material | SS400 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Grooving |

| Tool category | External grooving |

| Product name | AddForceCut |

| TSR No. | 118360G |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | QSG82-3T | 32x32 shank |

| Shank | CHTBR3232-120 | |

| Insert | QGS3-020 | 1 corner insert |

| Edges par insert | 1 | 1 |

| Cutting width | 20 | 20 |

| Grade | AH7025 | CVD grade |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 500 | 500 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 100 | 100 |

| Feed f (mm/rev) | 0.15 | 0.05 |

| Coolant | Internal | Internal |