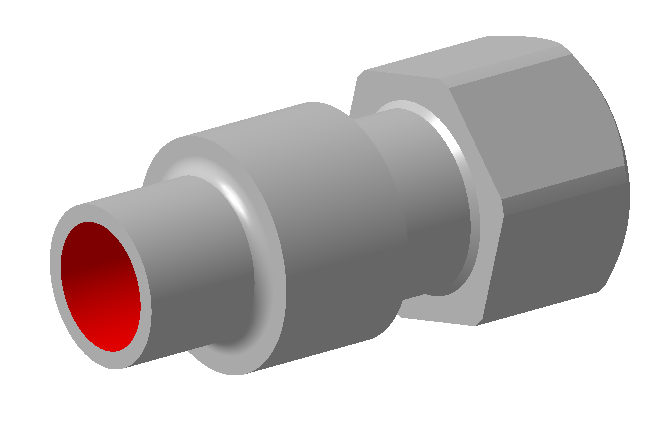

DrillMeister -Fittings Valve- DMM AH9130

IMPROVED TOOL LIFE

The drilling process for low-carbon steel connector components faced challenges due to poor chip evacuation and short tool life resulting from the lack of internal coolant supply.

Tool life was primarily determined by chip control performance, as the current drill could only process 1,500 pieces.

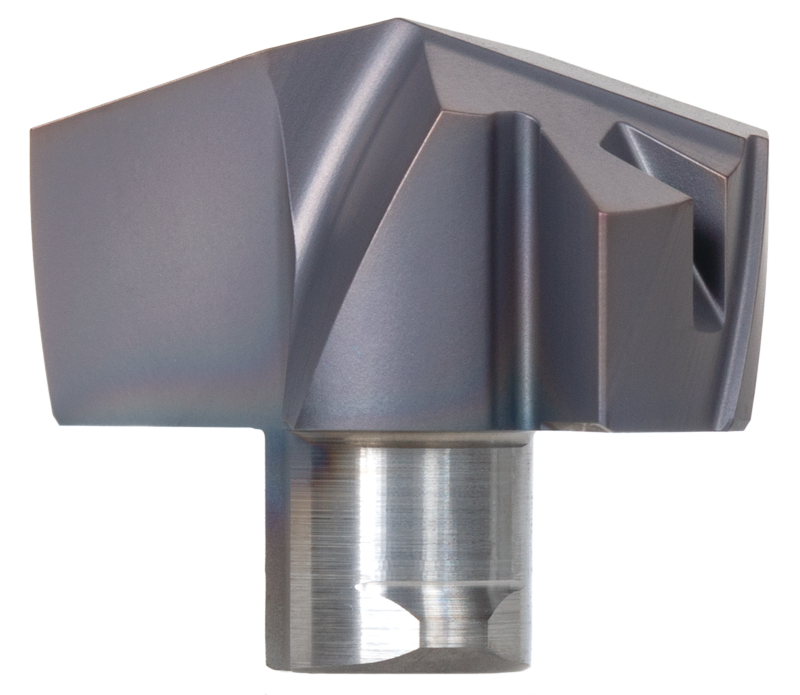

The DrillMeister DMM head, with its uniquely designed thinning geometry, ensures stable chip handling even in highly ductile materials like low-carbon and stainless steel.

Ultimately, tool life improved by 30% compared to existing products, leading to reduced machining costs.

Share

| Industry | Engineering |

|---|---|

| Component | Fittings Valves |

| Material ISO code |

|

| Work material | C1020 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Holemaking |

| Tool category | Drilling |

| Product name | DrillMeister |

| TSR No. | 5378H |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TID125F16-5 | Head exchangable drill 5xD |

| Head | DMM127 AH9130 | Drill head |

| Grade | AH9130 | PVD |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (m/insert) | 105 | 79 |

| Number of workpieces (pcs/insert) | 2000 | 1500 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 105 | 79 |

| Hole tolerance grade | IT11 | IT11 |

| Hole depth H (mm) | 52.5 | 52.5 |

| Cutting speed V/c (m/min) | 80 | 80 |

| Feed f (mm/rev) | 0.19 | 0.19 |

| Feed speed Vf (mm/min) | 381 | 381 |

| Coolant | External coolant | External coolant |