DrillMeister -CVT pulley – DMP MCWMB

IMPROVED TOOL LIFE

The goal is to reduce costs in the drilling process for CVT shaft machining.

With the current drill, the drill head needed replacement after 1,500 units.

By applying DrillMeister's special grade "MCWMB", which is a premium material with excellent wear resistance, wear and chipping of the cutting edge were significantly suppressed. This ultimately allowed stable processing up to 2,250 units, achieving significant cost reduction.

Share

| Industry | Automotive |

|---|---|

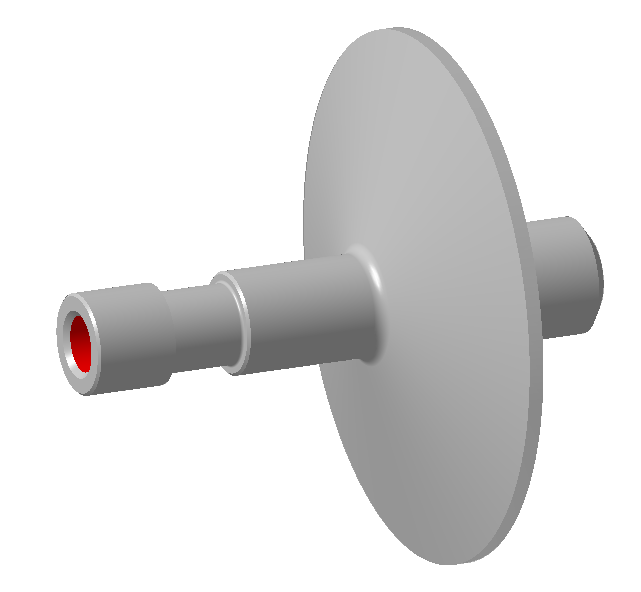

| Component | CVT Pulley |

| Material ISO code |

|

| Work material | SCr420 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Holemaking |

| Tool category | Drilling |

| Product name | DrillMeister |

| TSR No. | 5374H |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TID170F20-10 | Head exchangable drill 10xD |

| Head | DMC171 MCWMB (Special ) | Drill head |

| Grade | MCWMB | PVD |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (m/insert) | 351 | 234 |

| Number of workpieces (pcs/insert) | 2250 | 1500 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 17.1 | 17.1 |

| Hole tolerance grade | IT10 | TI10 |

| Pilot hole diameter (mm) | 17.1 | 17.1 |

| Surface quality required Ra (μm) | Rz12.5 | Rz12.5 |

| Hole depth H (mm) | 150 | 150 |

| Cutting speed V/c (m/min) | 81 | 81 |

| Feed f (mm/rev) | 0.3 | 0.3 |

| Feed speed Vf (mm/min) | 452 | 452 |

| Coolant | Internal coolant | Internal coolant |