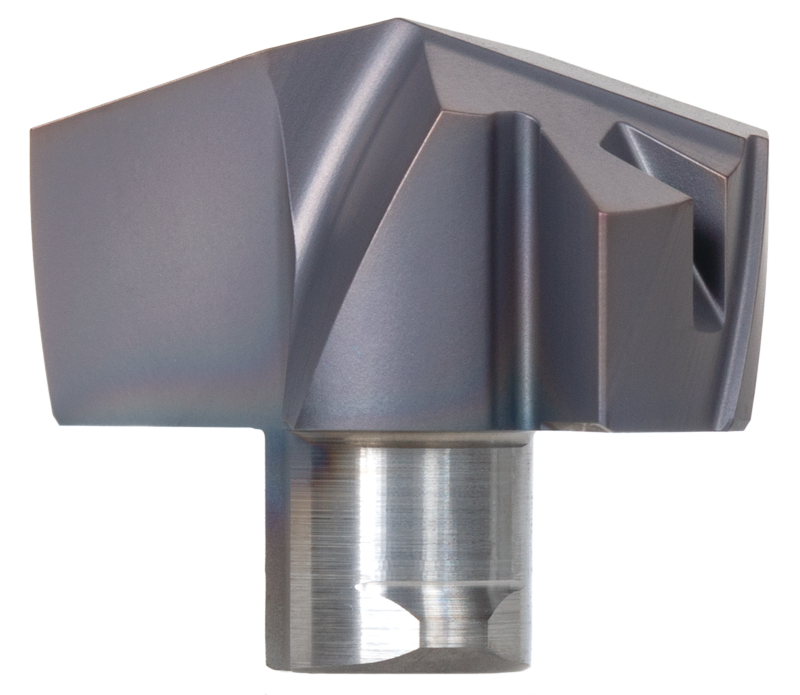

DrillMeister DMM head -Ni base component –

IMPROVED TOOL LIFE

The DMM geometry outperformed the current drill in Ni-based alloys.

Using the same cutting parameters, tool life was extended by 1.4 times.

The existing drill head had been a special item dedicated to Ni-alloy drilling, whereas we achieved even better performance with a standard item.

Share

| Industry | Power Generation |

|---|---|

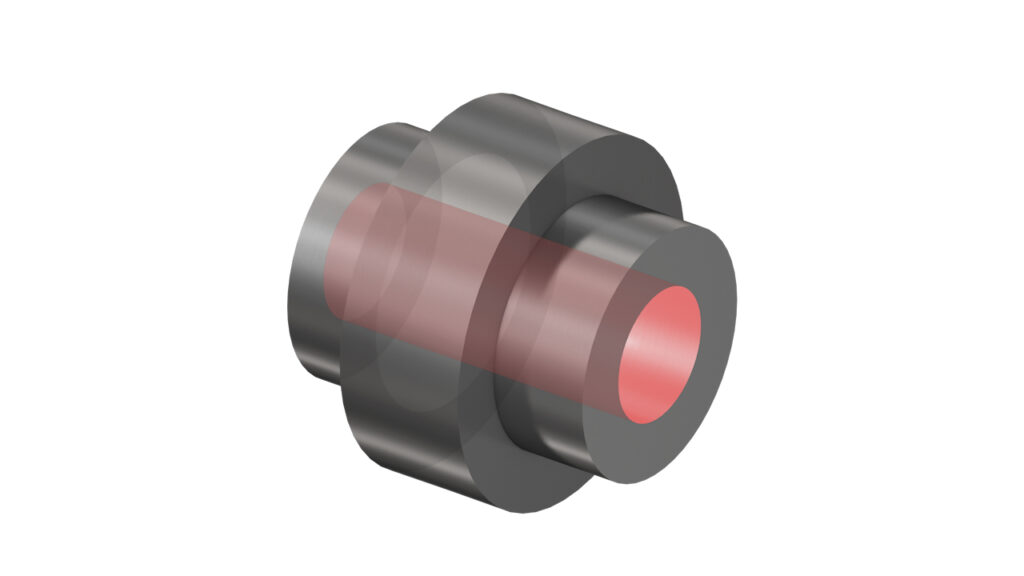

| Component | Shaft Parts |

| Material ISO code |

|

| Work material | Ni base alloy |

| Machine(spindle type) | CNC Lathe |

| Tool family | Holemaking |

| Tool category | Drilling |

| Product name | DrillMeister |

| TSR No. | 5364H |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TID120F16-5 | Head exchangable drill 4xD |

| Head | DMM120 AH9130 | Drill head special geometry |

| Grade | AH9130 | PVD |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (m/insert) | 26 | 18 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 12 | 12 |

| Hole tolerance grade | IT10 | IT10 |

| Hole depth H (mm) | 45 | 45 |

| Cutting speed V/c (m/min) | 23 | 23 |

| Feed f (mm/rev) | 0.1 | 0.1 |

| Feed speed Vf (mm/min) | 61 | 61 |

| Coolant | Internal coolant | Internal coolant |