DrillMeister DMM head – Valve –

IMPROVED TOOL LIFE

The DMM geometry outperformed the current drill in stainless steel machining.

With the same cutting parameters, tool life was significantly improved.

By switching to DMM, the customer achieved approximately 9% savings on head consumption.

Share

| Industry | Oil & Gas |

|---|---|

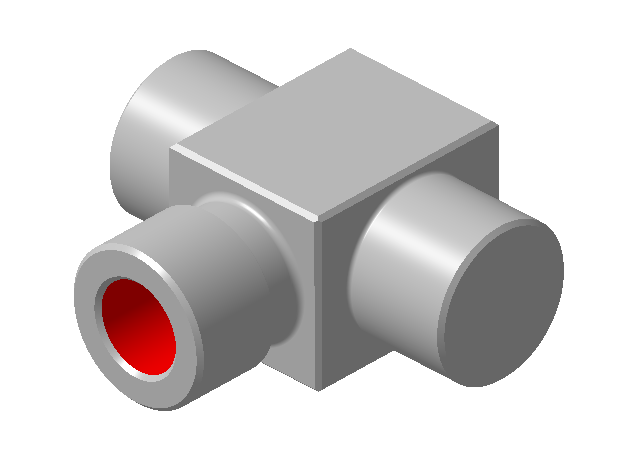

| Component | Valve |

| Material ISO code |

|

| Work material | SUS316L / X2CrNiMo17-12-3 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Holemaking |

| Tool category | Drilling |

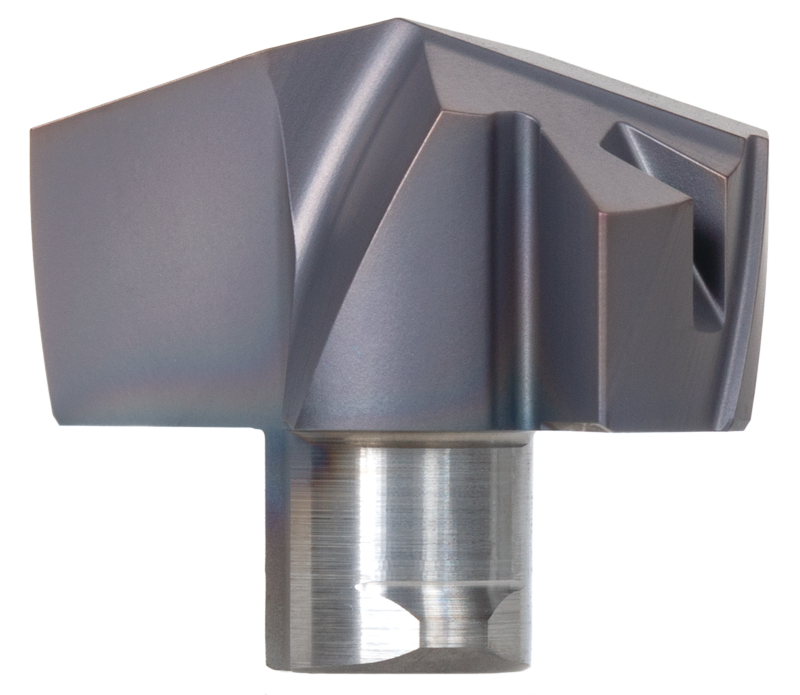

| Product name | DrillMeister |

| TSR No. | 5361H |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TID105F16-5 | Head exchangable drill 5xD |

| Head | DMM105 AH9130 | Drill head general purpose |

| Grade | AH9130 | PVD |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (m/insert) | 13.5 | 11 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 10.5 | 10.5 |

| Hole tolerance grade | IT10 | IT10 |

| Hole depth H (mm) | 41 | 41 |

| Cutting speed V/c (m/min) | 55 | 55 |

| Feed f (mm/rev) | 0.1 | 0.1 |

| Feed speed Vf (mm/min) | 250 | 250 |

| Coolant | Internal coolant | Internal coolant |