AddMultiTurn – Shaft – T9215

IMPROVED PRODUCTIVITY & TOOL LIFE

Tungaloy suggested the latest AddMultiTurn that allowed the use of high-feed back-turning method for the process, in which the competitor’s insert was being used with a conventional front-turning method. As a result, the customer achieved 2.1 times higher productivity and 4.4 times longer tool life per edge.

Share

| Industry | Machine Tool Builders |

|---|---|

| Component | Shaft of machine tools |

| Material ISO code |

|

| Work material | SNCM240 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | External turning |

| Product name | AddMultiTurn |

| TSR No. | 1736T |

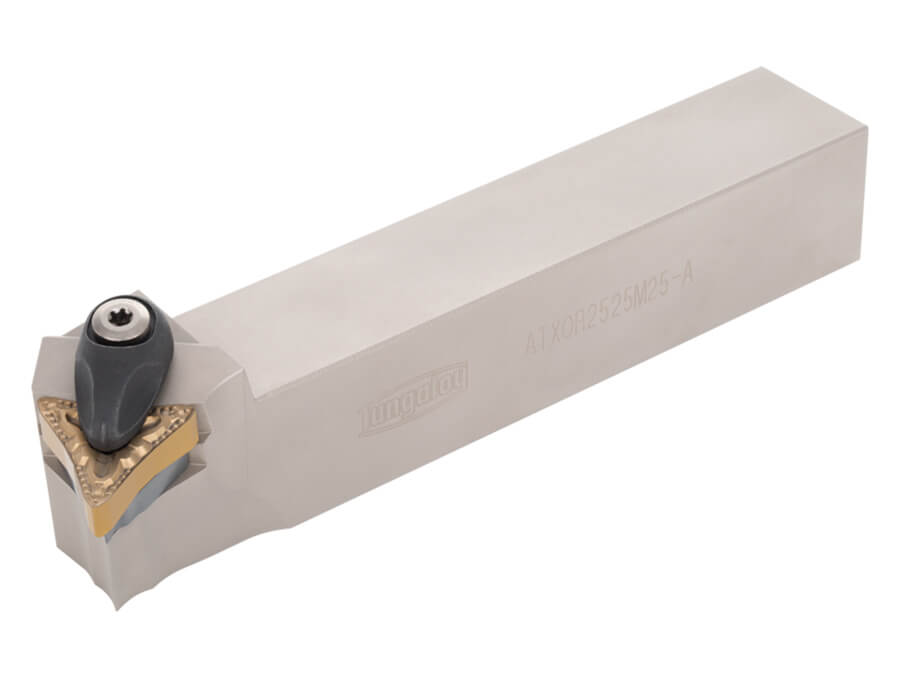

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | ATXOL2525M25-A | MWLNR2525 |

| Insert | 6C-TOMG250612M-TM | WNMG080408 With medium cutting chipbreaker |

| Grade | T9215 | CVD(P20) |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 40 | 9 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 280 | 280 |

| Feed f (mm/rev) | 1.2 | 0.28 |

| Depth of cut ap (mm) | 1.5 | 3 |

| Number of pass | 2 | 1 |

| Coolant | wet | wet |